Electronics and Power Generation

U.S. Computer Industry Is in Early Stages of Recovery; Electric Power Industry Rebounds from Cyclical Low-Point

U.S. Computer Industry Is in Early Stages of Recovery

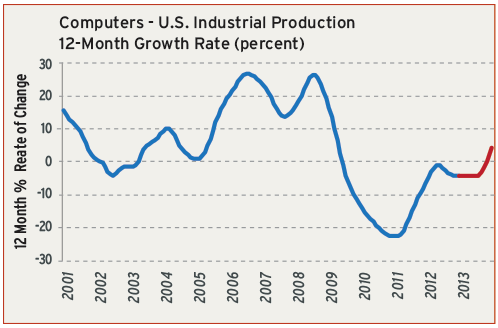

The total U.S. output of computers and peripheral equipment has declined every year since the Great Recession, but the downtrend has finally ended. The Fed’s data that measures monthly production of these products stabilized in the second half of 2012, and a recovery will start in 2013. The rate of improvement will be gradual through the first half of this year, but the industry will start to gain momentum in the second half. Our latest forecast calls for an annual increase of 4% in total output of computers in the U.S. in 2013. This follows a decline of 4% in 2012.

American production of computers and related equipment is 30 to 40% lower than it was prior to the recession. So we have a long way to go before the industry is fully recovered. Consumer demand for these products will be constrained in the short term by sluggish growth in personal incomes and employment levels. So the early stages of the recovery will be driven by business spending. At the present time, the economic fundamentals are favorable to increased investment in new computer equipment. Corporate profit levels are high and interest rates are low. The only missing ingredient is business confidence in the overall recovery. And this should improve noticeably this year.

The other factor that drives growth in this sector is the release of new technologies. Currently, there is no clear consensus on what "the next big thing" will be. There are some new products in the pipeline, but nothing that appears destined to be revolutionary. This can change quickly, so stay tuned. There may also be some re-shoring of computer production from overseas. Apple has expressed a desire to manufacture more of its products in the U.S. It is too early to tell if this is merely a symbolic gesture or the start of a bigger trend.

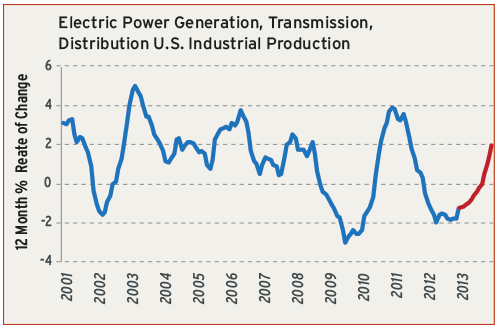

Electric Power Industry Rebounds from Cyclical Low-Point

The electric power industry suffered its second straight year of decline in 2012. This is surprising given the fact that the overall U.S. economy grew at a moderate rate of 2.2% last year. It is unusual for there to be a decrease in the production of electricity during a period of overall economic expansion, so it is unlikely that there will be another decline in 2013. Our forecast calls for total U.S. GDP to grow by more than 2% this year, and we expect that annual generation, transmission and distribution of electricity will expand by at least 2% as well.

The good news for manufacturers who supply this industry is that America's electric power infrastructure desperately needs to be updated. The problems associated with an aging infrastructure are less acute in years when production levels are down. But as the U.S. economy and its appetite for energy start to grow at a more robust rate, these problems will receive more attention and more funding. Many technologies already exist that will greatly improve the way electric power is generated and transmitted, all that's lacking is the impetus to invest in them.

There are two major trends in the electricity market that have already started and are quite likely to gain momentum in the coming months. The first is an acceleration in the conversion to natural gas as a fuel for generating electricity. The second is an increase in the number of motor vehicles that are powered by electricity. The energy markets are large and complex, so it is difficult to predict their short-term dynamics. It is quite likely that the market will change very little during the next two years, but it will change dramatically over the next 10 years.

Related Content

Dynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

Read MoreThe Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreEditorial Guidelines: Editorial Advisory Board

The Editorial Advisory Board of MoldMaking Technology is made up of authorities with expertise within their respective business, industry, technology and profession. Their role is to advise on timely issues, trends, advances in the field, offer editorial thought and direction, review and comment on specific articles and generally act as a sounding board and a conscience for the publication.

Read MoreRead Next

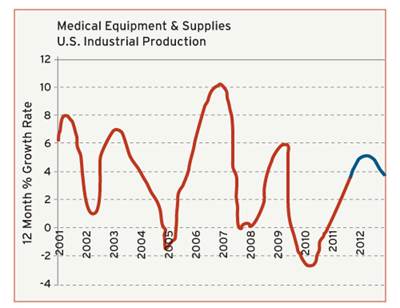

Medical Equipment and Supplies; Consumer Goods End Market Report 2012

Medical Equipment and Supplies; Consumer Goods.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)