Photo Credit: (Top left) Hasco, (top right) Zygo, (bottom left) Teknics ZeroClamp USA and (bottom right) Ingersoll Cutting Tools.

In addition to the mold components technology roundup this month, MMT has compiled several newly released or improved product offerings geared toward improving the performance, efficiency, flexibility, reliability and ease of use for your shop’s operations. Options range from a large-format metrology system with extended work volume up to 650 x 650 mm, to equipment with precise positioning and high clamp force for your workpieces and a new enclosed modular unit that can be directly mounted on a hot runner.

Categories covered include:

- Machining

- Hot runners

- Cutting tools

- Inspection/measurement

- Automation

- Maintenance, repair and surface treatment

Hasco’s new drilled thermal insulating sheets help prevent uncontrolled heat dissipation into the machine clamping plates from heated injection molds and compression molding tools. Through their high thermal compressive strength, they are particularly suitable for use in highly stressed molding tools.

YG-1’s newly introduced FM10 PNMU face milling indexable inserts combine multi-corner face milling performance with high feed capabilities.

The FM10 PNMU inserts are designed to separate the cutting edge and the wiper, which results in ten true cutting edges.

Oerlikon HRSflow has developed a mechanical stroke regulator (MSR) for hydraulic driven valve gate systems that reportedly makes it easy to individually preset the opening positions of the pins in hot runner systems. Using a graduate scale adjusting screw, the user can specify the individual oil volume, which the valve gate system then uses to bring the needles into the intended positions. In this way, the pressure drop for each nozzle can be set independently, and the pressure distribution during the packaging phase can be controlled.

Hasco’s hot runner’s proven range of needle valves has been supplemented by a new pneumatically driven, enclosed needle valve unit.

Based on the existing hydraulic version, this new modular unit is an enclosed system in which the operating piston and the connections are built into a compact housing. The module can be mounted directly on the hot runner via a flange construction and is used primarily for fully wired and piped systems.

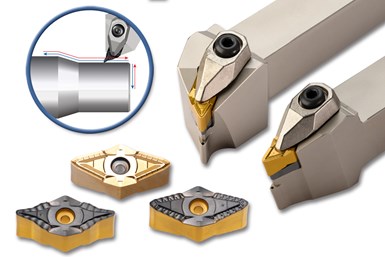

SuperTurnZ offered by Ingersoll Cutting Tools is an innovative system for multi-directional turning that utilizes the front and back cutting edge of a four-corner insert in a single tool. It reportedly represents a highly productive alternative to conventional turning; traditionally, where 80- and 35-degree corner inserts are fed in the same direction, SuperTurnZ uses all four directions available on conventional two-axis lathes (+Z, -Z, +X, -X) to maximize material removal.

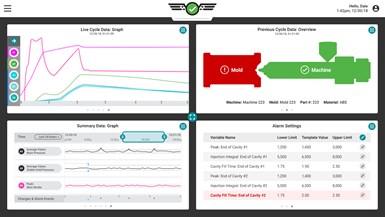

Injection Molding Process Control System Provides Traceable Data and Valve Gate Control

RJG’s CoPilot injection molding process control system is designed to be a user-friendly platform for producing high-quality parts. The CoPilot system enables users to observe what is happening to the part and identify when a process strays from the template, according to the company.

Ransohoff, a division of the Cleaning Technologies Group LLC, has introduced its Cell-U-Clean Cell Jet spray cabinet. This new, small footprint wash and blow-off machine platform provides an energy-efficient, reliable solution for high-volume cleaning, along with an innovative design for smaller part cleaning applications.

Mechanical cycle counters A5730HT and A57300HT, which can be used wherever there is a need to monitor process data, mark a further addition to the Hasco counter range. As a high-temperature version, the cycle counters can be used at temperatures of up to 200°C

Frigel North America enters a new market sector with the introduction of air-cooled portable chillers into its product line. Frigel contends that the industry’s highest energy efficiency ratio is among the unique advantages for customers of air-cooled portable chillers into its product line. Frigel contends that the industry’s highest energy efficiency ratio is among the unique advantages for customers.

Zygo Corp. announces the launch of the Nexview 650, a large-format metrology system designed as an inspection tool for the automated measurement of injection molding tooling, PCBs, glass panels and other samples requiring an extended work volume up to 650 x 650 mm. The system provides 2D and 3D measurements of a variety of surface features with sub-nanometer vertical precision and sub-micron lateral precision.

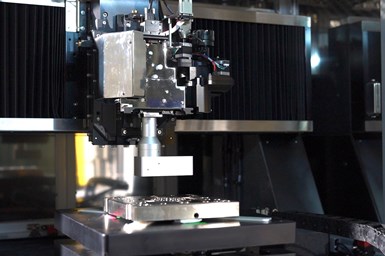

Mitsui Seiki’s new PJ 303X five-axis machining center is reportedly capable of processing workpieces up to 230 mm tall, 280 mm in diameter (9" x 11") and 20 kg (44 lbs) in weight. According to the company, typical applications include lens molds, medical products, EDM electrodes and fuel cell components.

Mitutoyo America Corp. has added AI Inspect to its software lineup. Mitutoyo AI Inspect is a standalone software product designed to assist customers with next-generation visual defect analysis across multiple applications.

The software’s headlining features are the distinct Training Module and Runtime Module. The first of these enables users to develop inspection routines for automated implementation of defect detection using image sets, while the Runtime Module incorporates these inspection routines into the system.

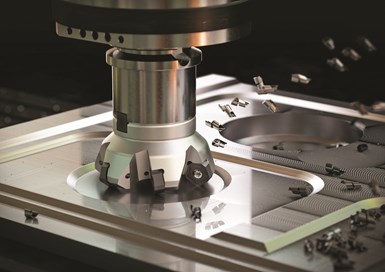

Teknics ZeroClamp USA has introduced its Zerolox XP 80Z Zero Point workholding automation console, which is made in Germany. The Zerolox Console provides a universal interface that enables precision positioning for clamping five-axis self-centering vises, pallets and workpieces on three, four and five-axis CNC machines.