Designed by Firefighters and Molded in the USA

It's always interesting to learn something unique about our niche audience, and this New York molder/moldmaker offers up just that ... with its own line of fire, rescue and safety products.

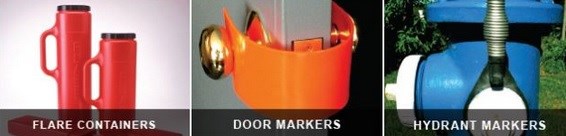

The CY Plastics motto is "Molding your ideas into shape," which is evident with its venture into designing, manufacturing and selling a line of fire, rescue and safety products, which includes flare containers, hydrant markers, door wedges, and standard and custom-stamped door markers.

Andy Molodetz, president of CY Plastics explained to me how this product line came about, "The company acquired a small moldmaker whose owner was also a third-generation firefighter. He had created molds for several useful firefighting products, and had a loyal fan base among fellow firefighters as well as first responders, police departments and institutional administrators. After having acquired the molds, we continued to make and sell those products directly to the end users and also through distributors. It’s a good fit for us."

Andy points out three specific reasons:

1. Since CY can do both blow molding and injection molding, they can create the entire product. For example, blow-molded flare containers with matching injection-molded caps and mounting brackets.

2. CY's in-house mold maintenance department can keep the molds in prime condition through welding, sand blasting, creating new ejector pins, etc.

3. They can offer customized products by creating inserts to add text or features to the molded part, or through secondary operations such as custom text stamping or machined cut-outs.

CY Plastics designs and manufactures these products near Rochester, NY. They are available for sale on the CY Safety Products webstore and through a network of wholesalers.

Related Content

-

VIDEO: Insights and Best Practices for Mold Care

Slide Products President Michael Muth shares the products and practices he believes have helped the moldmaking industry the most when it comes to caring for molds.

-

Mold Solutions Target Safety, Storage and Productivity

NPE2024: Globeius and its suppliers are showcasing solutions focused on decreasing downtime, reducing energy consumption, increasing safety and more in an injection mold shop.

-

Tool Caddy Safely Stores Cutting Tools

The Kaiser Manufacturing Tool Caddy makes it convenient for the operator to grab toolholders without any risk of cuts.