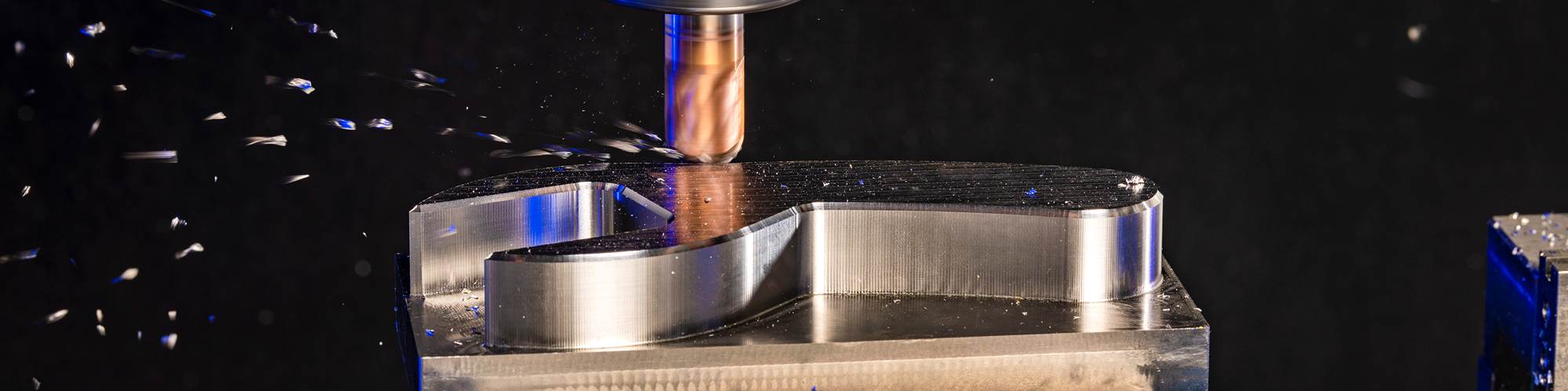

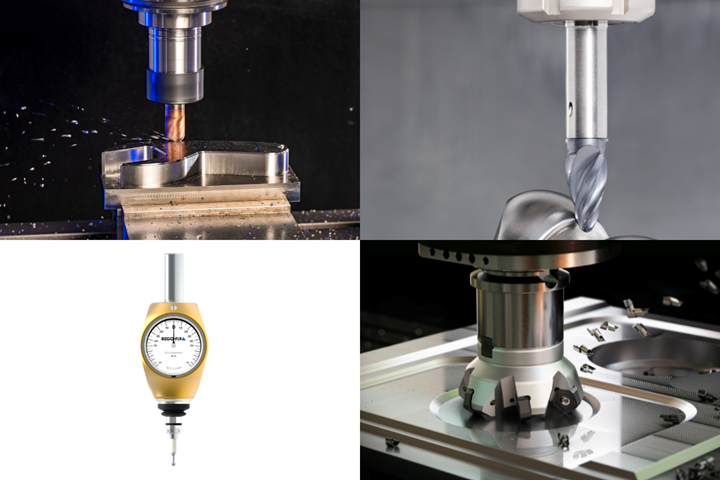

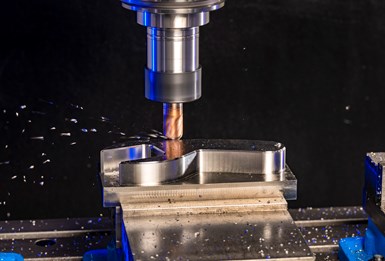

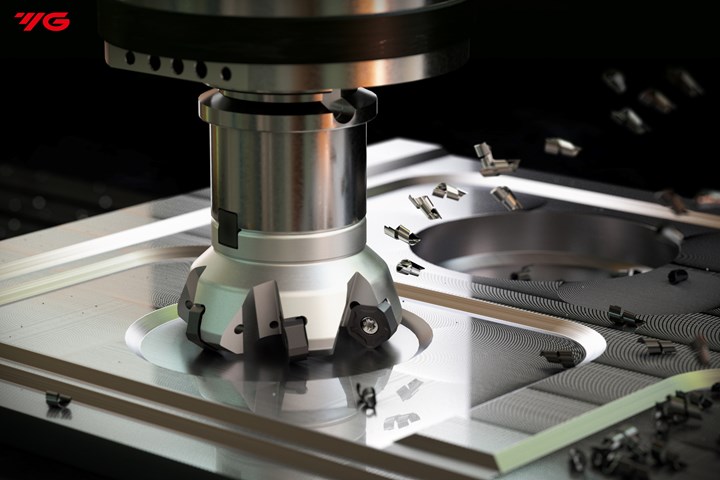

Photo Credit: (top left) IMCO Carbide Tool, (top right) Iscar USA, (bottom left) Rego-Fix and (bottom right) YG-1.

Innovations will be abundant at IMTS 2022, which takes place at McCormick Place in Chicago, Illinois, from September 12-17. Professionals from all over the industry will be present to showcase their new products and services, and attendees will get a glimpse of the future of manufacturing as they peruse the show floor.

To prepare you for the event and help familiarize you with some of the products and exhibitors that will be present, MoldMaking Technology has compiled our product coverage below. Click on the company name to be taken to the full product post and learn about what you can expect to see at IMTS.

This installment features cutting tool innovations, but be sure to keep an eye on MMT’s website for more exhibitors and products to be featured in the lead-up to the event (see “Machining and EDM Innovations to Look for at IMTS”).

Related Content

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreTreatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More