Coping with Hard Part Milling

Machining hardened stock isn’t for the faint of heart, but many alert shops have figured out how. In fact, some are running steels up to Rc 60 four or five times faster—even in cavity work.

Machining hardened stock isn’t for the faint of heart, but many alert shops have figured out how. In fact, some are running steels up to Rc 60 four or five times faster—even in cavity work. Others have even found a way to mill the hard stuff on light-duty machines using conventional end milling.

“Hard materials are less forgiving, so everything matters more when it comes to the milling process,” says Bill Fiorenza, product manager at Ingersoll Cuttings Tools. “Also, tool life is a bigger factor in overall process economics. Minimizing stoppage time for indexing can often save more machining money than ramping up the feedrate.”

Five Times Faster on Mold Blocks

One impressive recent success is at Datum Industries, a die and mold shop in Grand Rapids, MI. Not surprisingly, a mainstay in their diet is cavity milling of hardened molds and mold blocks.

With a simple tooling change, Datum now roughs the blocks five times faster and has completely eliminated a semi finishing operation. Their previous standard tooling was a conventional ½-inch four-flute solid carbide ballmill. Now they do it with a two-flute indexable Ingersoll Chip-Surfer™ high-feed mill with a bull nose tip. Settings follow the modern “feed fast/cut shallow” strategy—400 ipm/0.020”DOC/3855rpm. That’s 10 times faster feed than before. Stoppages due to tool wear are way down as well; just once every 15 hours, done in seconds, right in the spindle. On a material-removal basis that’s a 25 to1 saving in both downtime and tool inventory cost.

And nobody knows this better than John Smith, process engineer at Datum, “The roughed finish is good enough to let us go directly to finishing now. We not only feed 10 times faster during roughing, but also take a much wider swath, cutting chipmaking time two ways.”

The Chip-Surfer tool itself is essentially an alloy steel shank that accommodates a variety of replaceable carbide tips. Datum chose the high feed tip, which has two flutes and a bull nose cross section. The bull nose moves more of the tip’s active cutting surface out near the pitch radius, so that more of the tool is moving at optimum cutting speed. Geometry on a spherical carbide ballmill, by contrast, means that optimum cutting speed can occur only at the midline.

More Secure Milling of A-2 Stock

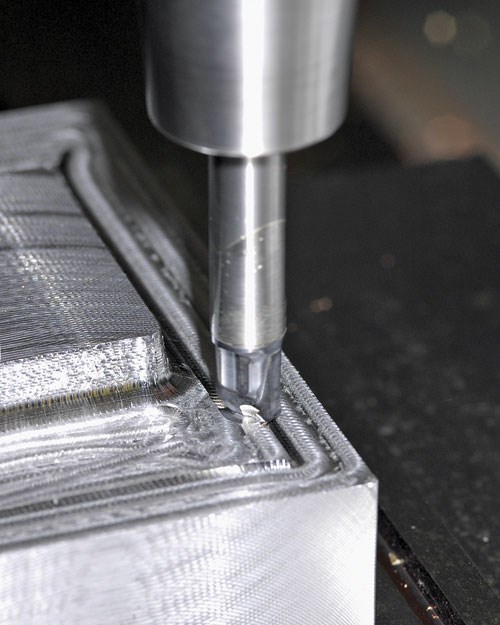

At moldmaker B&J Specialties (Wawaka, IN), the key problem running hardened A-2 stock was tool failure of solid carbide ball with mills. Whenever time process engineer Scott Sizemore turned up the feedrate, the cutters either wore out or broke off within minutes. So he pretty much settled for a 100 ipm/0.004” DOC/3750 rpm machining rate. With the switch to an Ingersoll Chip-Surfer with a toroidal tip, he could double the feedrate and triple the depth-of-cut (DOC), leading to an overall threefold gain in cavity throughput. Despite the higher settings, edge life also tripled, with in-spindle tip changes taking only 20 seconds. Each tip consistently lasted a full hour.

Toroidal-tip Chip-Surfer In the cut at B &J Specialties. In hardened A-2 die stock, the tool outpaces solid carbide ballmill by 3 to1 in cavity roughing and more than tripled tool life

“We’re literally roughing 3.5 times faster and finishing 6 times faster than before,” says Sizemore, “with similar gains in edge life per unit of material removed.”

The toroidal tip features a robust sweeping radius to capitalize on chip thinning, with generous corner radii and back draft to clean out corners faster without overloading the tool. “Cavity milling is essentially side milling with high lateral forces, which is where the ductile alloy shank comes in,” adds Fiorenza. “It tolerates the flexure forces that can easily snap off a carbide shank—especially on hardened stock.”

Taming a Bear

15-5 ph steel hardened to Rc40 has grown in popularity among moldmakers because of the way it polishes. But at the cavity roughing stage, it’s a bear, according to Minco Tool and Mold (Dayton, OH). Even at very low machining rates, it cratered the inserts on their standard four-flute zero-rake indexable cutter at unacceptable rates.

“We could live with the slowness, but not the tool failure rates or the mode of failure,” says Minco procurement manager Glenn Mullins. “Early failure of one edge by predictable wear would still leave with us with up to three more useable edges, but sudden cratering ruins the entire insert.”

So Minco went the extra mile to optimize rough milling of the bear. “It’s the material of the future, so we need to do it well,” says Mullins. Accordingly he devised a test piece, brought in all of their mainstay tooling vendors to the same room and issued the identical challenge: here’s the problem, give it your best shot.

Two semifinalists finished the test piece in about half the time as before and much faster than the other competitors, with inserts lasting longer and wearing gradually. One was a five-flute cutter using four-sided inserts, the other an Ingersoll Power-Feed+™ three-flute mill with six-sided inserts. The former was slightly faster, but the latter won out on grounds of overall economy.

“Insert and indexing costs matter more in hard part milling, so we compared them carefully,” explains Mullins. “With fewer inserts in the cutter and more edges per insert, the Power-Feed+ would reduce our annual tooling costs by 70 percent compared with our original tool and 40 percent versus the other finalist.”

So now Minco mills its 15-5 ph twice as fast as before, at much lower tooling cost and with no catastrophic edge failure. As it turned out, tooling associated costs to mill the hardened material represented 35 percent of total machining cost. That’s more than 10 times higher than for milling softer stock. “This shows why tooling costs definitely merit more attention in hard part machining,” says Ingersoll’s Fiorenza. “Look for tools that both last longer and index faster.”

Minco Tool and Mold more than doubled cavity milling rate on increasingly popular but punishing 15-5 ph steel by switching to Ingersoll Power-Feed+ facemill. Minco settled on it after exhaustive tests to optimize machining of a mold stock that regarded as part of their future.

Not So Hard After All

Fiorenza offers these additional tips for successful hard part milling.

- Be sure the machine is rigid. Hard workpieces can exacerbate any looseness in the machine or fixturing.

- Manage heat. Hard part milling will generate more of it. Spindles that are air cooled and designed to minimize heat flow back to the machine frame are preferred.

- For cavity work, opt for high-end software with look-ahead capability. That plus careful programming can keep chip loads uniform in and out of corners. In any metal, you don’t want to have to slow down at each corner, yet you can’t afford transient chip loads able to snap off a tool. Be especially careful of it in hard materials.

- Choose robustly designed cutter bodies with extremely secure seating and quick indexing capability. In inserts, look for geometries that reduce cutting forces and fine grained microstructures with improved shock and impact tolerance.

“Everything that matters in milling matters more in hard part milling,” concludes Fiorenza.

Read Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More