Amerimold 2019: Free Tech Talks Focused on “What You Should Know”

Amerimold 2019 free presentations focus on what moldmakers should know about conformal cooling, venting, skilled workforce crisis, mold maintenance, IMD and public policy.

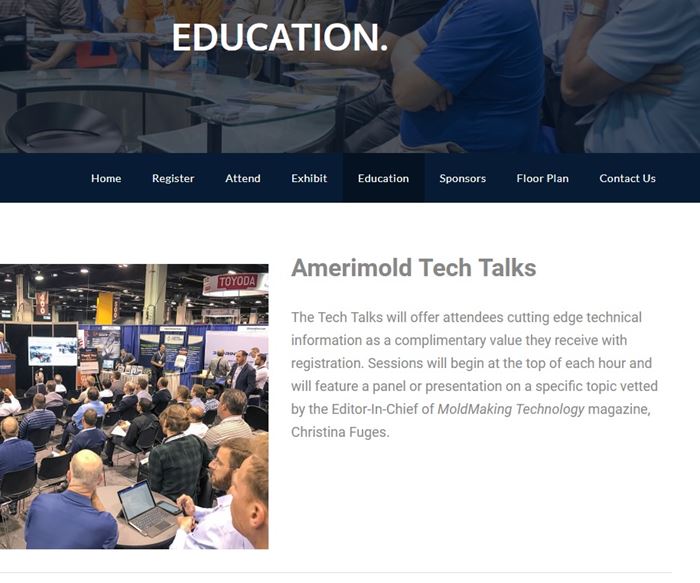

I centered Amerimold 2019's free show floor Tech Talk program around “What You Should Know”. Here is a snapshot of the sessions:

What You Should Know about Additive Manufacturing for Conformal Cooling: Additive manufacturing (AM) and 3D printing are hot topics in molding and mold manufacturing that are often misunderstood. This panel discussion will present in detail the different AM technologies available today, their advantages and disadvantages, and specific ways to implement these technologies without issue. ALBA, ROI Industries, Crest Mold, Contura, HTS International, Linear AMS, Proper Group

What You Should Know about Getting Venting Right: This presentation will review several ways to get your venting right, including guidelines for designing and machining vents to optimize venting capacity, proper vent amount, location, width and depth, using a vacuum/blowback venting system and modifying the tool for vacuum venting, using and designing with self-venting mold material and installing the most efficient mold components, such as vacuum vent blocks and venting valves. Estée Lauder, Tri-Par Mold, CAE Services

What You Should Know about the Skilled Workforce Crisis: Panelists will share best practices for how to develop a plan to build and diversify a next-generation manufacturing workforce, how to develop the right strategy and program for effective apprenticeships/skills training and how to engage with industry and the community to find, train and retain a diverse next-generation workforce. Human Asset Management

What You Should Know about Improving Your Third-Party Mold Maintenance Culture: Improving the care and performance of third-party molds requires a commitment to a plan. Husqvarna and Mold Trax have teamed up to review this action plan and discuss the barriers to systemize and change the mold maintenance and repair culture across multiple facilities. Mold Trax,Husqvarna

What You Should Know about a Mold Builder’s Role in IMD Work: This presentation will review the various challenges a tool shop must consider before and during IMD. For example, how will the location of the in-mold film determine the gating location? Which method for film placement and control is the most robust (static charge, vacuum or steel feature)? What kind of impact does the IMD process have on the price of the injection mold? Are there any general best practices for IMD mold design? Are any special steel surfacing/finishing techniques required about the film? Is there a limitation to the number of cavities in the production mold? Can process/molding simulation technologies be used to help ensure success? SussexIM, StackTeck

What You Should Know about Excellence in Mold Manufacturing: MoldMaking Technology’s 2018 and 2019 winners will share best practices in customer satisfaction, workforce development, industry involvement, continual improvement, business growth, and technology deployment. 2019 Winner TBA, 2018 Winner Maximum Mold Group

What You Should Know about Public Policy: This panel will review trade and tariff updates and their impact on mold manufacturing, plastics and die casting markets; exchange rates and how they affect export/import competitiveness; what’s happening in work-based learning, apprenticeship programs and government assistance programs; and, the latest on the innovation front, including Smart Factories and their impact on U.S. manufacturing. Alliance for American Manufacturing, MSI Mold Builders, Janler Corp.

Looking forward to seeing you in Rosemont on June 12 & 13! Register Today!

Related Content

Snapshot of Why Dynamic Tool Corp. is MMT's 2024 Leadtime Leader Winner

Here is a quick look at some of the reasons this 40-plus-year-old engineered tooling solutions provider took the title this year.

Read MoreMore Than Moldmaking at PTXPO 2023

The Moldmaking Pavilion returns to the Plastics Technology Expo (PTXPO) March 28-30, 2023, at the Donald E. Stephens Convention Center in Rosemont, Illinois, but there’s more to discover than moldmaking.

Read MoreTackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read More2024 Outlook: Anticipating Trends and Opportunities for Mold Builders

The January 2024 issue lineup sets the tone for the variety of topics, technologies and trends that we will cover this year.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More