Amerimold 2017: Technology and Techniques, Talks and Talent

Tech Talks covered everything from trends in equipment and products to business strategies and training.

- New hybrid (milling/sintering) machine technology virtually eliminates EDM, reduces part warpage and dramatically reduces cycle times when producing mold inserts

- A new, multi-layer 3D robotic-deposition process can used for conformal cooling to reduce the number of required baffles or bubbler systems, as well as gun drilling and tapping.

- Automated five-axis machining/EDM cells with the right planning, routing, prioritizing and communicating can offer a cost-effective alternative to series and batch mold manufacturing.

- Simulation tools that analyze part size and shape, simulate the effects of gate position, material properties, heating and cooling circuits to identify and avoid weld lines, air traps, surface defects, sink marks and short-shot moldings can opitmize the mold build process and mold and part quality.

- Data can be used to communicate your value proposition, employ activity metrics, pipeline analysis and win/loss attribution data, create lead generation programs, invest in CRM tools, take advantage of media and public relations, develop SEO-optimized content, inbound marketing and customer surveys, establish standards and implement financial controls.

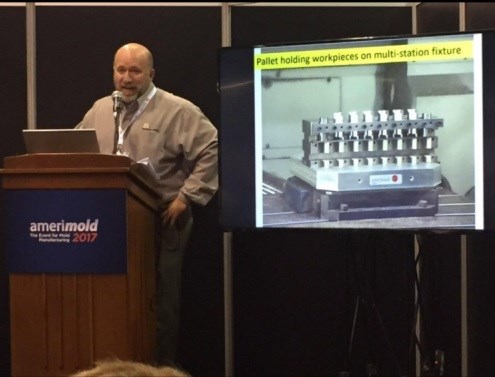

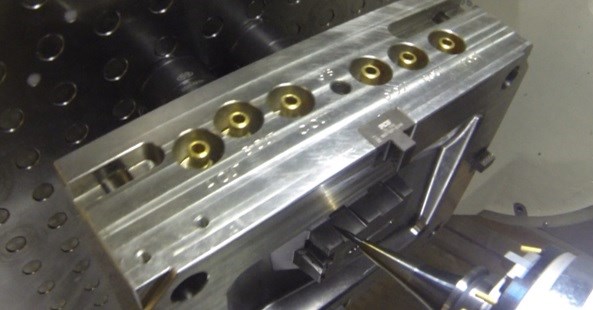

- Machining can be optmized with the right five-axis CNC HMC with 30,000-rpm spindle speeds and 1,000-psi through-spindle coolant capabilities, a 120-position toolchanger, an integrated, expandable robotic 10-pallet changing system, and a modular clamping system that positions a workpiece within the machine tool for machining as many as five sides in one setup.

- “Smart” machines are those that compensate for fluctuations before rejects are produced; “smart” production includes high vertical and horizontal data integration; and “smart” service involves condition-based, predictive maintenance.

- Only by using metrics can you measure and set preventative maintenance frequencies and calculate unscheduled mold stop costs.

- Combining high quality milling strategies with the right toolpath editing and optimization tools can drive CNC machines exactly as required, and CAM integrated with collision-checking and avoidance permits three- and five-axis machines to run unattended, freeing up the workforce to tend to other duties.

- Eliminating chatter in very deep machining applications requries cutting tools designed specifically for that application.

- The only way to maximize metal-removal rates and stabilize performance metrics is to have best practices.

- Passive cooling devices on hot-runner actuators and valve pin monitoring allow for less complex mold designs, requiring less maintenance compared to traditional water-cooled units.

- Recent developments in hot runner technology allow the fine-tuning of melt flow and volume in selectable parameters, improving the process as well as both cosmetic and part performance characteristics.

Tech Talk particpants included:

- Phoenix Deventure, Jeff Christian, CEO

- MGS MFG Group, Kevin Klotz, Simulation Services Manager

- Conformal Cooling Solutions, Pat Zaffino, Managing Director

- Cimatron Software, 3D Systems, Ralph Picklo, Director of Sales

- Industrial Molds Group, Wes Stephens, Account Manager

- Erowa Technology, Nils Fagerman, Regional Manager

- Autodesk, Mark Hennebicque, Business Line Manager

- Precise Tooling Solutions, Don Dumoulin, CEO/Owner and John Rowe Director of Marketing

- Krieger Craftsman, Tim Krieger, President

- Leadtime Leader 2017 Winner, Graphic Tool

- Winzeler Gear, John Winzeler, Owner

- Mold-Rite Plastics, Bernie Banks, Assistant VP of Manufacturing

- MoldTrax Maintenance Solutions, Steve Johnson, President

- Paragon Die & Engineering, Dave Muir, President

- Autodesk, Clinton Perry, Product Marketing Manager–Manufacturing

- Haimer, Drew Strauchen, Vice President of Marketing and Business Development

- OSG USA, Steve McBride, High Tech Group Manager

- HTS International, William Sames, CEO

- HRSFlow,, John Blundy, President

- Synventive Molding Solutions, Greg Osbourne, Account Manager

Related Content

MMT Chats: Giving Back by Answering the Moldmaking Education Need

MoldMaking Technology Editorial Director Christina Fuges checks in with Bruce Cateon, an executive advisor at OASIC Consulting. Bruce started out in moldmaking, eventually becoming an industry consultant and taking time to work on his passion project the “Injection Mold Design Handbook” as a way of giving back to the industry that has given him so much. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreConfronting the Mold Design Talent Drought

Recently, I reposted on LinkedIn the results of an informal survey we conducted, which revealed a shortage of skilled mold designers. It quickly gained a lot of traction. Given the response, I thought I'd summarize the feedback and keep the conversation going.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreMaking Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More