Aerospace/Defense and Energy/Power Generation

Defense Suppliers Hoping to Avoid “Fiscal Cliff” and Energy Production Accelerating

Defense Suppliers Hoping to Avoid “Fiscal Cliff”

Unless Congress gets its act together and makes some changes, the Defense Department’s budget will be slashed in 2013. This is part of the deal that Congress crafted (and I use the word loosely) last summer as the solution to the debt ceiling debacle that was underway at the time. Congress has yet to pass a budget that would lower the Federal budget deficit, so automatic tax hikes and spending cuts are scheduled to go into effect on January 1, 2013. Ben Bernanke, the Chairman of the Federal Reserve Board, has dubbed this a “fiscal cliff” because it would most surely push the economy into a recession.

It would also significantly diminish this country’s national defenses. We can intelligently debate whether we are presently getting the maximum value out of the Defense Department’s budget, but the cuts that are currently proposed are far too drastic at this time. Nevertheless, it is unlikely that anything will be done to rectify this issue before the election. So the way it looks now is that we will have to wait until after the election. At that time we will have to rely on a lame duck Congress with precious little time to act.

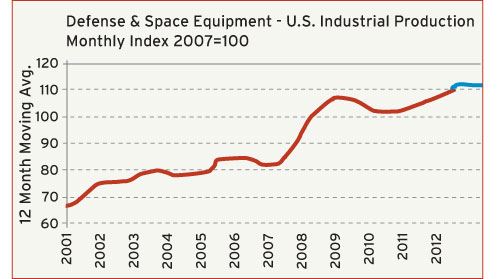

The chart shows that spending on defense equipment has risen steadily in recent years, and under normal circumstances, that is the trend we would expect to see for the foreseeable future. Putting the arguments about fiscal policy aside, this country’s long-term defense strategy will focus more on enhanced technology and less on large land and sea forces. Think unmanned aircraft (a.k.a. drones) rather than battleships and tanks.

Energy Production Accelerating

If the U.S. is going to expand its economy and enhance the overall prosperity of its citizens in future generations, then we must increase our output of domestically produced energy. In fact, this is the biggest problem/opportunity that the American manufacturing sector currently faces: how to develop a reliable supply of clean, abundant energy. The good news is that we are finally starting to step up to the challenge.

Production of natural gas has increased substantially in recent years. So has the output of energy from solar, wind and geothermal. But we need more, a lot more. To meet our needs we must not only find new ways to generate energy, but we must develop more efficient means of transmission and distribution. We must also be more efficient in our use of energy products. This will require better machines, building materials and motor vehicles.

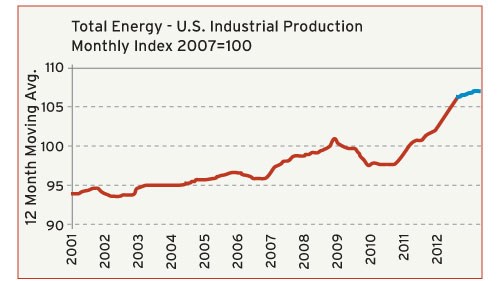

After a decline in the recession year of 2009, total U.S. output of energy has expanded by about 3 percent per year on average. We will have to maintain a rate of growth of at least this much over the next few years if we are to grow our economy, raise employment and achieve energy independence. The critics will say that it is too expensive, but when all of the real costs to our nation are considered, I argue that the status quo is too expensive. Energy production will continue to escalate in this country, and this represents a huge opportunity for our entire manufacturing sector, particularly the mold and die segment.

Related Content

Editorial Guidelines: Editorial Advisory Board

The Editorial Advisory Board of MoldMaking Technology is made up of authorities with expertise within their respective business, industry, technology and profession. Their role is to advise on timely issues, trends, advances in the field, offer editorial thought and direction, review and comment on specific articles and generally act as a sounding board and a conscience for the publication.

Read MoreTop 10 Topics to Cover During an ISO 9001 Manufacturing Audit

Take a look at this practical hands-on approach to conducting a quality audit.

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreMMT Chats: Solving Schedule and Capacity Challenges With ERP

For this MMT Chat, my guests hail from Omega Tool of Menomonee Falls, Wisconsin, who share their journey with using enterprise resource planning (ERP)—and their people—to solve their schedule and capacity load monitoring challenges.

Read MoreRead Next

Tapping into the Energy/Environmental Markets

The energy/environmental markets are broad and burgeoning for Mack Molding.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)