3D Printing Aids Both Short- and Long-Term Production Needs

Protolabs helped Specdrums nail down the design of Sepcdrums’s musical education tool with rapid injection molding.

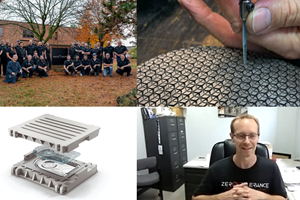

Driven by its incredibly successful Kickstarter campaign, Boulder, the Colorado-based, connected musical applications company Specdrums had a challenge on its hands. With orders in the queue, the growing company needed production help—they needed it fast, and in a manner that could scale for future growth.

The company’s rapid success has been due to its game-changing innovation that brings drumming to your fingertips, literally.

Specdrums started as a simple idea—founder Steven Dourmashkin asked, “What if we could give people an easy way to drum anywhere and use color to make different drumming sounds?” He invented fingertip drum sensors (rings) that pair with a mobile device. Using the Specdrums app, a player can assign musical notes and sounds to specific colors. When the player taps the ring on the color, it plays the assigned sound.

In late summer 2017, it took Specdrums just 30 days to exceed its Kickstarter goal by 1,250 percent. After receiving an unbelievable number of pre-orders, the company was faced with finding a manufacturing partner to deliver the silicone parts it needed to meet demand. Before shipping to customers though, it needed samples to get into the hands of product influencers and educators.

Rapid injection molding creates what Specdrums needed in the short-term as well as the ability to scale as the company continued to grow.

Accelerating a Cool Idea with Digital Manufacturing

Dourmashkin created his own production molds at first. But with the volume of demand, this quickly became inefficient. The next step was looking into rapid injection molding, a process that created both what Specdrums needed in the short-term as well as the ability to scale as the company continued to grow.

The process wasn’t without its challenges. When looking for a molding partner, some companies Dourmashkin met found the design to be problematic. One of the parts had an overhang, which added complexity to the design. It wasn’t until Dourmashkin came across Protolabs that he knew he had found the right team.

Specdrums used Protolabs’s applications engineers and design for manufacturability analysis to identify improvements to the design, improving fit and durability. It created 3D-printed samples to nail down the design before developing molds and low-volume production tools for injection molding. Being able to iterate through this process quickly was key.

“I admired Protolabs’s willingness to work with my designs and improve the manufacturability. Other manufacturers were worried about the overhang and weren’t willing to improve the design with me,” Dourmashkin says.

During the design process, one of Protolabs’ applications engineers suggested Dourmashkin look into the Protolabs Cool Idea! Award. Entering and being awarded the grant enabled Specdrums to refine the product even further, without delaying time-to-market. With the ability to do on-demand small production runs, Dourmashkin could test colors and materials to create a high-quality product, allowing the company to fulfill all the orders to its Kickstarter backers by January 2018.

It created 3D-printed samples to nail down the design before developing molds and low-volume production tools for injection molding. Being able to iterate through this process quickly was key.

An In-Demand Educational Tool

In 2018, the Specdrums team developed STEAM and music education programs to accompany the drum rings and app. A majority of interest has come from STEAM educators, special needs teachers, makerspace managers and artists from across the world.

Amy Abbott, a K-5 music teacher in Colorado, was able to use Specdrums with her students. “It’s different, it’s unique, and nobody else has them. I haven’t yet met a kid who doesn’t like them, and teachers need them for classrooms,” Abbott says. “A lot of kids are hesitant to use music, including kids on the autism spectrum. Specdrums can be an engaging tool to get them involved in music. The colors and sounds are engaging in a new way.”

After commercializing the product, Specdrums was acquired by another Boulder-based company, Sphero, which is well-known for its connected toys and educational tech products. Dourmashkin and his team will retain oversight of Specdrums and will have more resources to help with engineering and marketing to further the growth of the product. The ability to prove both the market and the manufacturability of the product was critical in the acquisition.

“It was really Protolabs that got us to this point,” Dourmashkin says. “Without the help of its team, we would not be as far ahead as we are today.”

Related Content

3D Printing Innovates Hot Runner Manifold Design

Metal 3D printing combined with a conventionally machined manifold block overcomes flow shadows on valve gates and offers faster color changes while providing closer system pitch centerlines between cavities.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreMold Materials, 3D Printing Technologies for Next-Gen Moldmaking

As moldmaking advances, so too do the materials and processes involved in their efficient production, including these latest mold materials and 3D printing technologies.

Read More4 Keys to a Successful Mold-Building Operation, The Latest Mold Design Tips & More

MoldMaking Technology is off to a strong start this year with mold design tips, key considerations for running a mold-building “business,” polishing pointers for ribs and more. Check out our list of top-viewed articles from January and see what catches your eye.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More