Spotting Press Matches Mold Parts from an Ergonomic Position

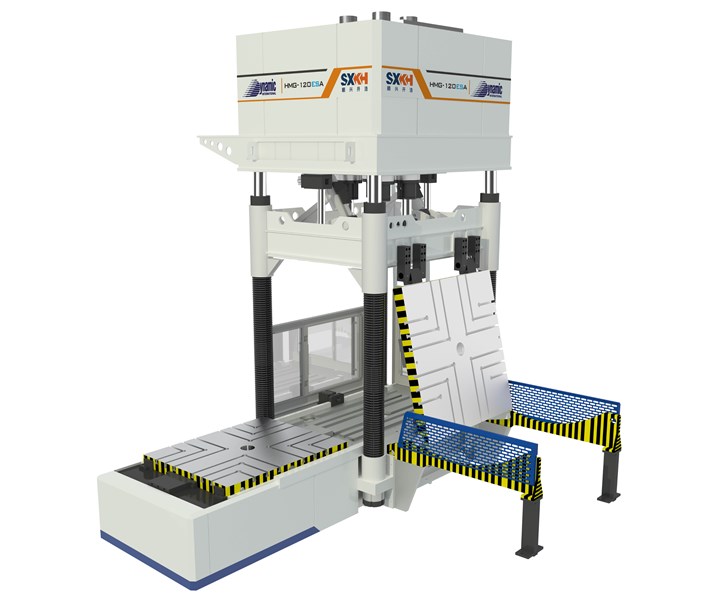

The SXKH spotting press from Dynamic International enables users to match all the parts of a mold in a more comfortable, ergonomic position.

The SXKH spotting press from Dynamic International enables users to match all the parts of a mold in a more comfortable, ergonomic position. The high standard of configuration ensures high performance, and all the main components for mechanical processing are manufactured by imported machining center to ensure machining precision. The spotting press’s shift-out rail of the lower mold plate adopts wear resistant rail with intensified handle and large-scale dust-proof device. Hydraulic system adopts optimal combination of imported high performance hydraulic elements.

The press uses a high tensile rod to provide higher accuracy, making it convenient for platen parallelism adjustment. Four molding clamps distribute stress when the mold is closed with high pressure. Using a quick cylinder device, the press speeds up null stroke without mold closing, creating lower energy consumption and more energy conservation. Parameters are displayed on a touch screen, and it provides practical failure detection alarm and low-pressure mold protection functions. The press is marked with a Certificate of Conformity.

Related Content

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

-

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

-

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

.jpg;maxWidth=300;quality=90)