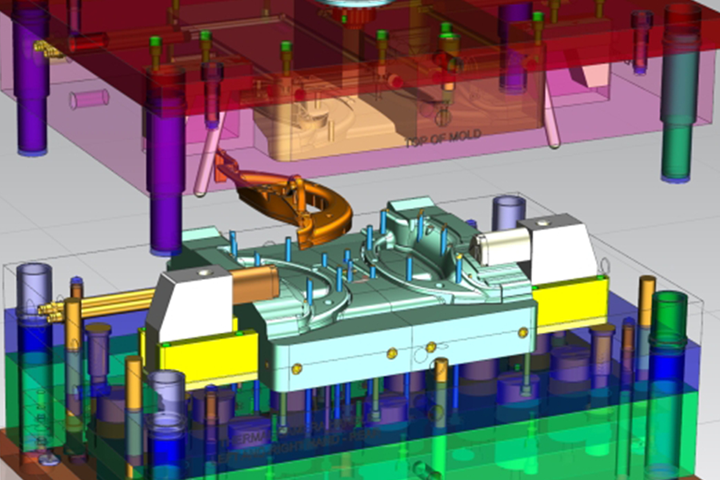

Siemens NX Mold Wizard for Next-Gen Mold Designers

Offered by Amerimold exhibitor Swoosh Technologies & Solutions, the CAD software increases productivity, virtually test performance, produce drawings and create CNC data, all within the same system.

Photo Credit: Swoosh Technologies & Solutions

Swoosh Technologies & Solutions, a Siemens Digital Industries Software Platinum Partner, presents Siemens NX Mold Wizard to Amerimold 2021 attendees. Created for the next generation of mold designers, it is built on a powerful product development system: Siemens NX. According to the company, the CAD software providers users the tools necessary to increase productivity, make changes faster, virtually test performance, produce drawings and create CNC data, all within the same system.

From providing structured workflows and automation of mold-specific design tasks to libraries of standard mold components, Mold Wizard creates a step-by-step process that is said to promote the most efficient workflow. Mold Wizard also integrates complex elements of design technology into automated sequences, provides comprehensive data import options with native formats for third party files and performs manufacturability checking to evaluate designs for moldability. With these analysis aids, designers can verify parts and compare differences when they need changes. Automatic drawing creation is also available.

Exhibitor: Swoosh Technologies & Solutions

Booth 624

Related Content

-

Moldmaking, the Relentless Pursuit of Innovation … Oh Yeah!

Innovation was at the root of the presentation lineup for the 2023 MoldMaking Conference, which included a heavy focus on automation, collaboration and communication, as well as mold design, talent development, reshoring and sustainability.

-

VIDEO: Explaining MoldMaking Versus Mold Manufacturing

To understand how training has been impacted we first need to understand the differences between a few key concepts. What is moldmaking vs. mold manufacturing? Who is a mold designer vs. a mold engineer?

-

More Than Moldmaking at PTXPO 2023

The Moldmaking Pavilion returns to the Plastics Technology Expo (PTXPO) March 28-30, 2023, at the Donald E. Stephens Convention Center in Rosemont, Illinois, but there’s more to discover than moldmaking.

.jpg;maxWidth=300;quality=90)