Optimized AM Metal Powder Alloy Delivers Application Flexibility

New high-temperature, crack-free nickel-chromium alloy from EOS North America opens up industrial 3D printing options.

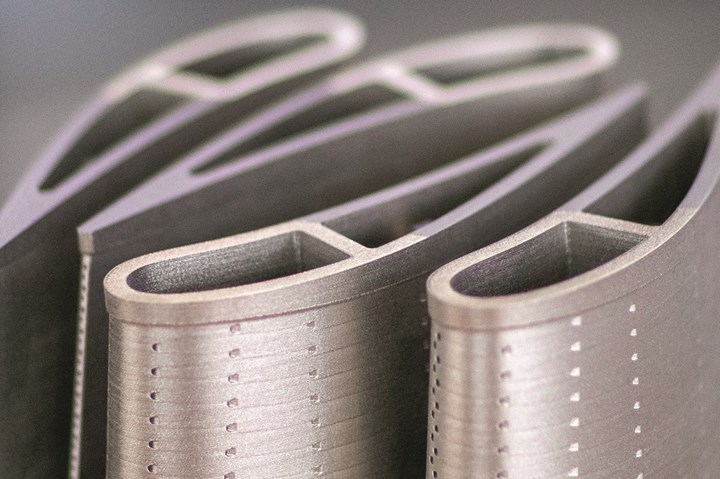

Photo Credit: EOS North America

EOS North America, an industrial 3D printing technologies supplier for metals and polymers, has added a new nickel alloy material to its growing list of metal powders available for use in powder bed additive manufacturing (AM).

The new material, EOS NickelAlloy IN939, is a nickel-chromium alloy that is said to offer a balance between strength in high-temperature settings, resistance to corrosion and oxidation, fatigue performance and creep strength at temperatures up to 850ºC (1,560ºF). EOS says its NickelAlloy IN939 provides users with improved tensile properties, validation, reliability and crack resistance compared to similar materials currently on the market. Parts produced using EOS NickelAlloy IN939 can also be hardened after being manufactured by applying precipitation-hardening heat treatments.

Available for processing on the EOS M 290 metal AM platform, EOS says the material’s improved qualities position it for more flexible industrial application use, particularly for applications that are exposed to high temperatures and extreme elements.

In addition to the immediate availability of EOS NickelAlloy IN939 for the EOS M 290, there is a planned release for the EOS M 400-4 platform in Q2 2021, and other future platforms.

Related Content

-

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.