Microscale 3D Printer Pivots Prototyping and Short-Run Production

BMF launched its microArch system globally in February 2020, just weeks shy of the pandemic, and has installed more than 125 units around the world.

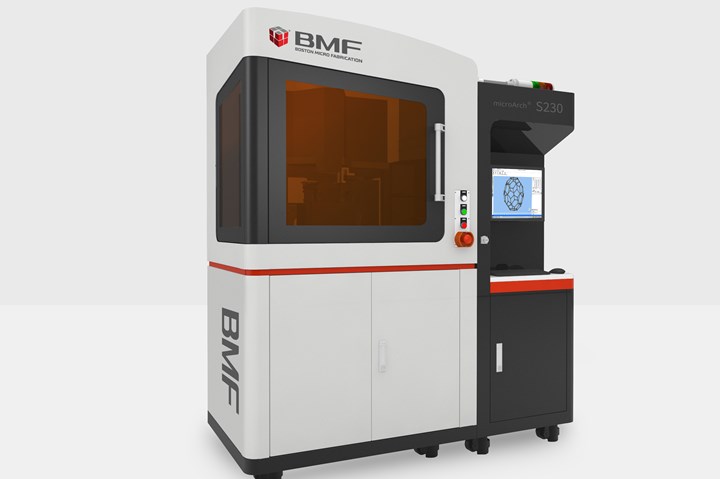

BMF’s microArch S230.

Boston Micro Fabrication (BMF) recently launched the microArch S230, along with three new materials. This next-generation version of BMF’s highest resolution system is designed for applications that require ultra-high resolution prints (down to 2μm) with reported accuracy, precision and speed.

The microArch S230 targets researchers and manufacturers needing micro parts with tight tolerances for prototyping through production. The printer is built upon BMF’s patented Projection Micro Stereolithography (PµSL) technology, a technique that allows for rapid photopolymerization of an entire layer of liquid polymer using a flash of UV light at micro-scale resolution, but with a larger built volume (50 x 50 x 50 mm) and up to five times faster prints than previous models in the 2μm series.

Additional key features of the microArch S230 include active layer leveling, automated laser calibration and the capacity to handle higher molecular weight materials with viscosities of up to 20,000 Cp, resulting in the production of stronger functional parts. The printer is compatible with a growing portfolio of engineering and ceramic resins suitable for end-use parts, including three new materials:

-

AL (Alumina) Ceramic: A biocompatible and chemical-resistant ceramic resin meant for high-temperature, high-strength and high-stiffness applications such as tooling (injection molding), casing and housings and medical devices.

-

HT 200: A durable, high-temperature and high-strength resin that can be soldered, and designed for end-use in electrical connectors and electrical components.

-

MT (Magnesium Titanate) Ceramic: The combination of high dielectric constant and low dielectric loss make MT Ceramic suitable for millimeter wave applications such as antennas, wave guides and other electronic components.

The system is optimal for end-use and prototyping use cases across industries that were once left out of the additive manufacturing landscape, including medical device manufacturing, microfluidics, MEMS, biotech and pharmaceuticals, electronics and electrical connectors, and research and development.

Related Content

-

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

-

Mold Materials, 3D Printing Technologies for Next-Gen Moldmaking

As moldmaking advances, so too do the materials and processes involved in their efficient production, including these latest mold materials and 3D printing technologies.

-

3D Printing Innovates Hot Runner Manifold Design

Metal 3D printing combined with a conventionally machined manifold block overcomes flow shadows on valve gates and offers faster color changes while providing closer system pitch centerlines between cavities.