New Alignment Options Machined From Parting Line

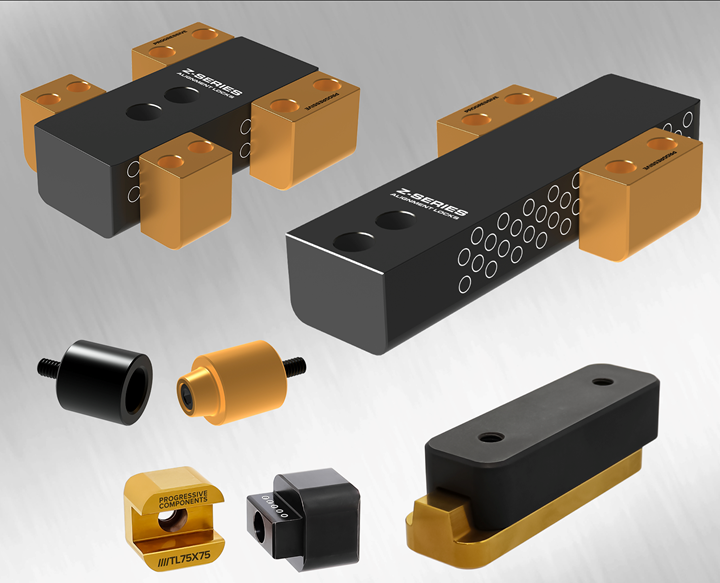

Progressive’s expanded Z-Series Alignment Lock options provide precision alignment of mold halves to protect shut-offs and to ensure parting line match.

Progressive Components has further expands its Z-Series Alignment Lock product line with the introduction of several new options for easier mold manufacturing.

Designed to be machined from the top at the parting line, new Top Machine Style Bar Locks simplify machining steps and increase pocket accuracy by enabling the alignment pockets to be machined on the same setup as cavity and core plate pockets. For multi-parting line tools, Progressive has also added an X-Style Bar Lock configuration. Both Top Machine and X-Style Bars are available in 3 sizes to pair with corresponding Guides.

To avoid waterlines and other mold features, new Internal Top Locks mount inboard versus at the mold base’s edge. They are available in 3 inch and 3 metric sizes (as well as shuttle sets) to provide a square footprint for maximum alignment with minimal space requirements. The new Counterbored Round Taper Lock is available in 5 inch sizes and provides counterbored mounting to enable parting line installation. In addition, new Rectangular Taper Bar Locks match industry standard sizing but extend performance with better materials and treatments utilized.

Progressive’s Z-Series Alignment Locks provide precision alignment of mold halves to protect shut-offs and to ensure parting line match. Each new Bar Lock, Guide and Internal Lock product is manufactured using patented Z-Series standards with proprietary materials and treatments to secure alignment throughout the life of the tool.

CAD geometry is available from the company's CADalog, a free parts library with downloads in multiple formats, including SolidWorks, NX, VISI, STEP, Parasolid, ACIS and IGES. Individual CAD files can be found at shop.procomps.com.

Related Content

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

-

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

.jpg;maxWidth=300;quality=90)