Moldmaker Commits to Continual Mold Manufacturing Improvement

M.R. Mold & Engineering, known globally for its LSR and plastic injection molds, continues to expand its expertise via new equipment, certification and into new industries.

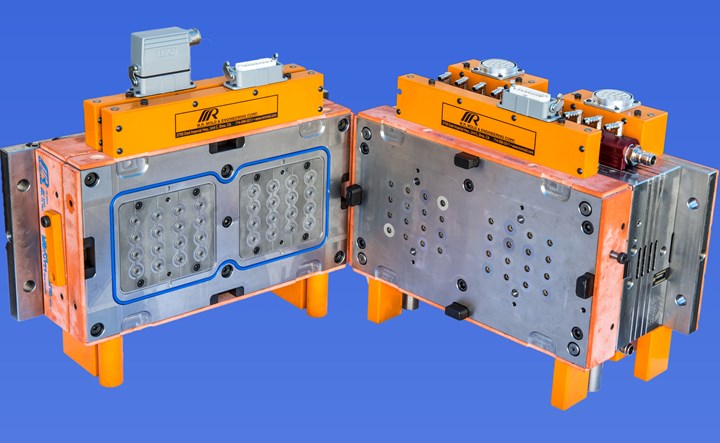

Photo Credit: M.R. Mold & Engineering Corp.

M.R. Mold & Engineering Corp., known globally for its expertise in liquid silicone rubber (LSR) for the medical industry, has been building LSR and plastic injection molds for more than three decades. With its recent acquisition of new equipment and pending ISO 9001-2015 certification, M.R. Mold says it expects to enter into the aerospace and defense industries.

The company-wide objective has been commitment to continual improvement in all phases of mold manufacturing, M.R. Mold notes. This is emphasized, not only in the high degree of precision expected and required from its skilled craftsmen for every high-end liquid silicone injection molds built, but the company’s mold Tech Center.

M.R. Mold’s Tech Center features six injection molding machines which are utilized for new mold qualifications/evaluations, R&D sampling as well as short run production. The company also features its own line of proprietary equipment, including a valve-gated cold runner systems, universal mold bases and material dispensing stuffer boxes.

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)