FMS Load Handler Targets Machine Tools Without Automatic Pallet Changers

The DMC-APC from Fastems can be configured into an FMS and load machine tools directly and act as an automatic pallet changer. Improved speed, machine tool utilization and reduced cost.

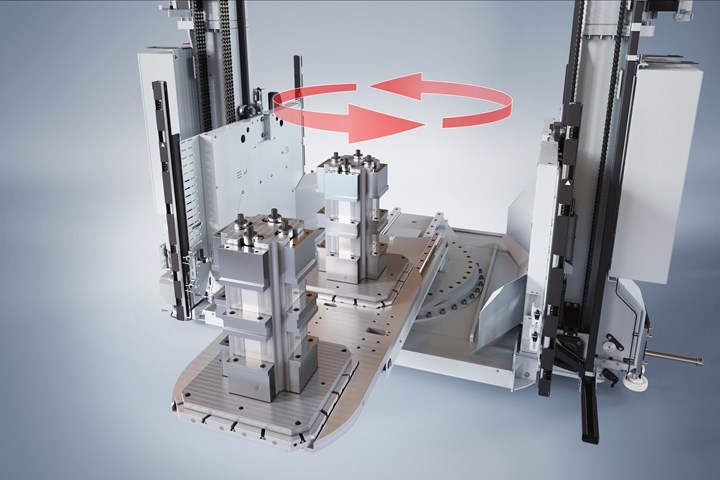

Photo Credit: Fastems LLC

Fastems LLC’s (West Chester, Ohio) new, multi-pallet load handler, the Double Mast Crane-Automatic Pallet Changer (DMC-APC) is a device that can be configured into an FMS (Flexible Manufacturing System) for machine tools that do not feature automatic pallet changers. Able to load machine tools directly and act as an automatic pallet changer, DMC-APC accommodates payloads up to 2,200 lbs (1,000 kgs). Further, says Fastems, manufacturers will no longer need to purchase and integrate costly APCs to machine tools in order to configure an FMS in their facilities.

In operation, the Fastems DMC-APC can accommodate up to two pallets. Controlled by the Fastems cell management software, the DMC-APC selects the next workpiece-loaded pallet from the storage system, moves it to an open machine tool, then picks up the previously machined workpiece/pallet from that same machine tool, spins 180º and places the new workpiece/pallet. This scenario takes about 30-40 seconds. In comparison, Fastems says, non-DMC-APC or classic stacker cranes typically accommodate one pallet, and the scenario would take about 100-120 seconds.

According to Fastems, there are several other notable benefits now that non-APC machine tools with higher payloads can be used in an FMS, namely surrounding speed, machine tool utilization and cost reduction. For instance, if the machining cycles are short, the necessity to make several pallet changes within one hour decreases machine tool utilization significantly. In addition to saving on time, the DMC-APC is also said to save floor space, as machines without APCs typically have a smaller footprint.

Related Content

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

.jpg;maxWidth=300;quality=90)