Flexible C Axis Facilitates Production of Precise Mold Contours

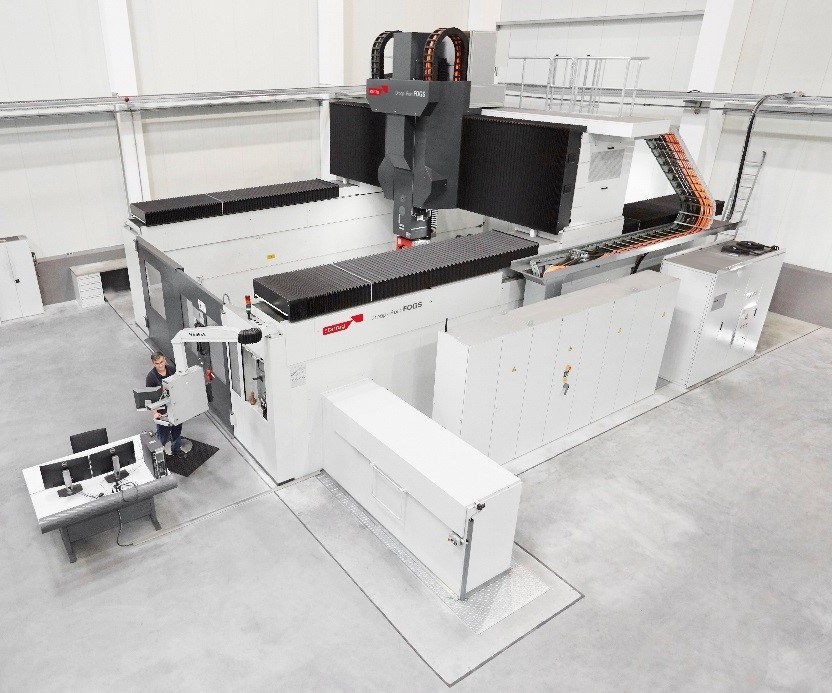

The Droop+Rein FOGS NEO machining center from Starrag USA features a C axis can be used for production of precise mold contours because of its flexibility.

USA Inc.Starrag Droop+Rein present the new machines at Amerimold 2018. The Droop+Rein FOGS HD from Starrag is an efficient high-gantry machine for precision machining. The X axis travels 3,000 to 31,000 mm, the Y axis travels 3,000 to 6,000 mm and the Z axis travels 1,500 to 2,500 mm. The FOGS HD also provides fast, dynamic axes and extremely high torque (2,400 to 7,500 Nm). It can rough and finish parts approximately 20–30 percent faster. In addition to the possibility of unmanned production, the FOGS HD also offers the option of a runtime-parallel setup in the machine.

Another option is the latest generation Droop+Rein FOGS NEO. The FOGS NEO is a high-speed machining center featuring a new milling unit and a modified C axis that, because of its flexibility, can be used for efficient production of highly precise mold contours. The C axis was extended from a maximum of ±200° to ±400°.

Related Content

-

MoldMaking Technology's Leadtime Leader Awards Competition Returns!

After a brief hiatus, MoldMaking Technology’s Leadtime Leader Awards Competition is back!

-

More Than Moldmaking at PTXPO 2023

The Moldmaking Pavilion returns to the Plastics Technology Expo (PTXPO) March 28-30, 2023, at the Donald E. Stephens Convention Center in Rosemont, Illinois, but there’s more to discover than moldmaking.

-

Moldmaking, the Relentless Pursuit of Innovation … Oh Yeah!

Innovation was at the root of the presentation lineup for the 2023 MoldMaking Conference, which included a heavy focus on automation, collaboration and communication, as well as mold design, talent development, reshoring and sustainability.

.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)