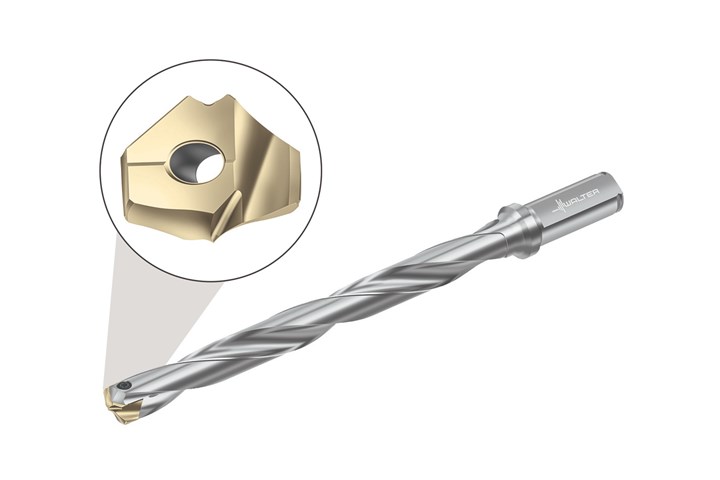

Exchangeable-Tip Drill Inserts Target Deep Hole Drilling in Low Carbon Steels

Walter launches the P6006 insert, which is ideal for holemaking without pilot drilling up to 10xDc in carbon steels, structural steels and low alloy steels.

Photo Credit: Walter USA

According to Walter USA, its P6006 insert for exchangeable-tip drills brings new levels of drilling efficiency to low carbon steels, structural steels and low alloy steels. Developed specifically for these materials, the insert features optimized geometry, with a sharp cutting edge and deep chip gash that leads to maximum process reliability and efficient chip breakage in low alloy or unalloyed steels. It also offers high centering accuracy, ideal for deep hole drills in the above-mentioned materials.

The P6006 insert can perform up to 10xDc without the need for a pilot drill. It features a protective chamfer on the insert with HIPIMS-PVD coating, and a wear-resistant WPP25 grade which leads to maximum tool life in stable conditions. Further, the insert has a 100° prism for the contact point in the body, and a 140° point angle with new geometry and thinner web. Optimum wear detection is provided by its light-colored yellow coating. The P6006's current diameter range is 0.472-1.161" (12.00-29.50 mm), with expectations to increase this range. Moreover, this exchangeable-tip drill is applicable for general metalworking, and the energy, automotive and aerospace industries.

The P6006 can be used in all exchangeable-tip drills D4140, D4240 and D4340.

Related Content

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)