ESPRIT Probing Cycle Option Improves CAM Software Setup and Accuracy

While probing is not new for DP Technology’s ESPRIT CAM software system, new features enable more versatility, part consistency and quality.

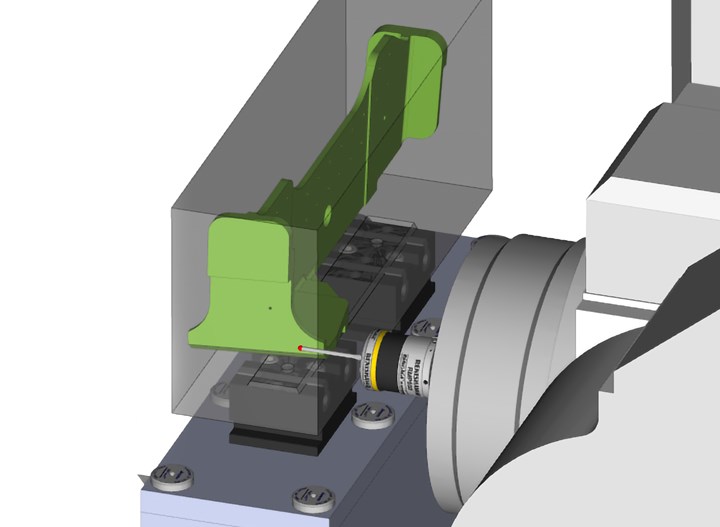

Photo Credit: DP Technology Corp.

DP Technology Corp., the parent company of the ESPRIT CAM software system, showcases a probing option that’s compatible with any combination of CNC machine, control and touch probe manufacturer. While probing—which uses a sensitive touch probe to assess the dimensions of the workpiece—is not new for ESPRIT, the company says the new features of the option are a valuable addition to the product.

New features added to the software’s probing support include:

- Offline inspection programming, which offers users the benefits of virtual stimulation for program verification and collision detection

- Hassle-free post-processing and full control over each probing routine

- Compatibility with more CNC machines and probe manufacturers

These new capabilities join the probing cycle’s existing features, such as misloading detection, which confirms correct part loading and reduces the risk of damage; on-machine inspection, which generates consistent measurements and eliminates manual measuring errors; and dynamic tool offsets, which automatically adapt the program considering tool wear.

Using the combination of ESPRIT probing and CNC machines outfitted with touch probes, DP says shops will enjoy increased throughput on existing equipment while reducing operator intervention. This benefit comes along with increases in part consistency and quality.

To help users fully understand the complete capabilities of the new add-in, ESPRIT has produced a free webinar, which can be accessed any time here.

DP Technology also announced a highly comprehensive ESPRIT 2020 update which improved support and machine tool solutions.

Related Content

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

-

Tolerancing in Mold Design, Part 1: Understanding the Issues of Conventional Bilateral Tolerancing

Mold designers must understand the location, orientation and form limitations of conventional tolerancing before changing to another dimensioning system.

-

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

.jpg;maxWidth=300;quality=90)