Diamond-Coated End Mills for Machining Electrodes

Adding on to Crystallume’s Standard Premium and Lightning coatings is Stealth, the company’s thinnest diamond coating for highly detailed moldmaking work.

Crystallume, known for its chemical vapor deposition (CVD) diamond technology, features its three diamond-coated tool lines — Standard Premium, Lightning and Stealth — for machining the thinnest details in graphite electrodes.

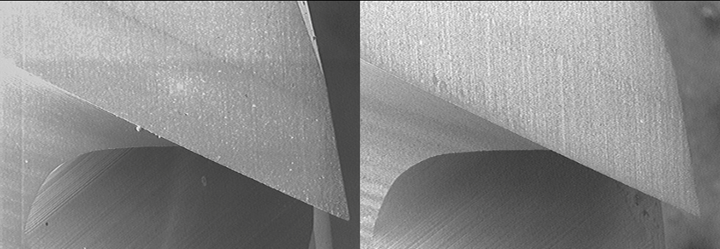

The company’s newest and thinnest diamond coating, Stealth, is only 2-3 µm thick, ensuring that tools with the coating have the sharpest solid diamond cutting edge available, according to the company. Depicted in the images above via scanning electron microscope is a cutting tool with the Stealth coating (left) and one without (right).

Four-flute Stealth end mill series are available, with a cutting diameter of 1/32 to ¼ and overall length of 1.5-4".

Related Content

-

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

.png;maxWidth=300;quality=90)