DeepTri-Drill Expands Drilling Depth Potential

In addition to the current lineup ranging up to 25xD, Tungaloy’s DeepTri-Drill now offers 35xD, 40xD and 45xD drill depths on standard CNC machines.

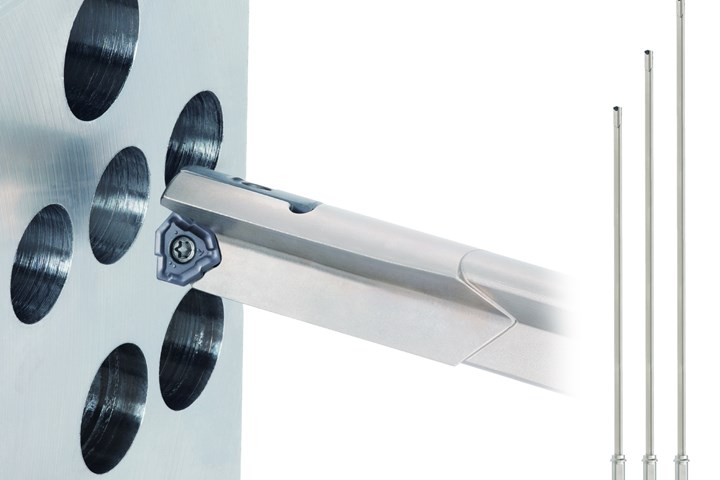

Photo Credit: Tungaloy America Inc.

Tungaloy America Inc. has added 35xD, 40xD and 45xD drilling depth capabilities to its DeepTri-Drill indexable insert deep hole drills.

DeepTri-Drill is designed to provide productivity and application security for drilling deep holes on standard machining centers and CNC boring machines, while ensuring easy tool management by eliminating the need for regrinding. The insert features chip splitters that enable effective chip evacuations for high feed rates during deep hole drilling in various materials. Inspired by BTA deep hole drilling technology, innovative insert geometry and optimal guide pad allocations on the drill body allow the production of high-quality deep holes equivalent to those made with traditional brazed gundrills.

In addition to the current lineup ranging up to 25xD, DeepTri-Drill now offers 35xD, 40xD and 45xD drill depths, further expanding its deep hole drilling potential similar to those found in injection mold and large-sized component manufacturing.

Related Content

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

.png;maxWidth=300;quality=90)