Configurable CAD Ordering System Reduces Redundant Mold Design Tasks

The release of Progressive Components’ CADalog v14 is geared towards simplifying custom component creation and ordering Mold-Ready components.

Photo Credit: Progressive Components

Progressive Components announces the release of its CADalog v14, a streamlined CAD offering for designers of injection molds. Available at no charge either online or via a flash drive, Progressive says its CADalog helps reduce redundant mold design tasks and is available in industry-standard formats for SolidWorks, NX, VISI, Parasolid, ACIS and IGES.

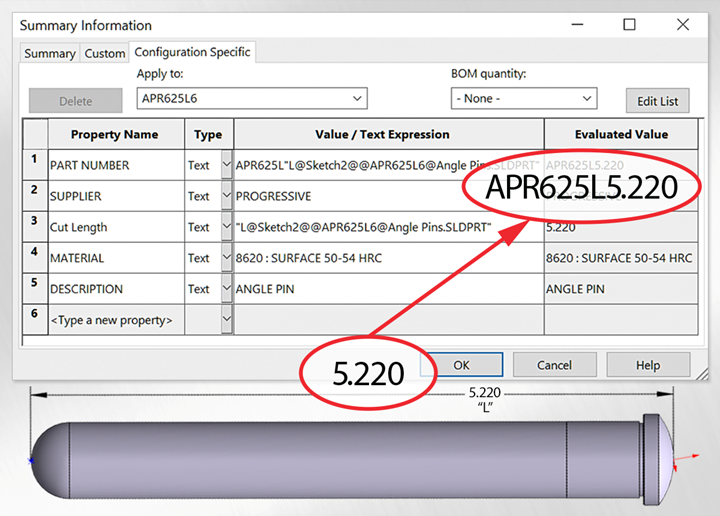

New to v14 are advancements geared towards simplifying custom component creation and ordering of Mold-Ready components. Mold designers who utilize the CADalog can now access a newly created SolidWorks library featuring configurable CAD geometry with populated attributes for ordering cut-to-length parts for products such as alignment locks, ejector pins and sleeves, UniLifters, angle pins, slide retainers, leader pins, bushings, support pillars and cooling items, and more.

In four easy steps, users can reportedly design parts using the Configurable CAD Library, automatically generate the Mold-Ready part numbers to enter into the BOM, send the finalized spreadsheet (BOM) via email to customer service, and then receive the customized parts quickly and ready for assembly.

To request a copy of Progressive’s CADalog, visit procomps.com/CAD. For additional information call 1-800-269-6653 or email tech@procomps.com.

Related Content

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.