Compact Mold Designs Demonstrate Sustainable Operations

In its quest for climate-neutral company, Haidlmair highlights five mold demonstrations live at the K Show with sustainable features, including molds for a six-drink crate, dolly deck pallet, reusable to-go cups and more.

Haidlmair is focusing its appearance at this year’s K Show entirely on sustainability. Attendees can learn more about its approaches for a reduced CO2 footprint in more detail, alongside other benefits of using its products. Visitors are also able to view the advantages of Haidlmair’s molds themselves, with five molds running live at various partner company booths.

The quest for climate-neutral company operations was achieved in August 2021, the company says. Next, Haidlmair focused on the sustainability of its own products, first through production of injection molds. Now, the company says it is able to determine the exact CO2 footprint for each mold — including data from the steel production, the company machining production and the upstream and downstream transport processes. Moreover, its compact mold designs — featuring optimized cycle times, longevity, low maintenance and low wear properties — and Haidlmair’s intensive involvement in the use of recyclates contribute to emissions reduction.

At the Haidlmair stand itself, a mold for a “6DC” (six-drink crate) is running. The mold is said to demonstrate an optimal design for the use of recycled material, the use of the Flat Die Unit (FDU), a hot runner technology from a Haidlmair subsidiary, and real-time monitoring and documentation of the production by Mould Monitoring, from Digital Moulds.

At the injection mold machine manufacturer, Engel, two Haidlmair molds are running — a mold for a dolly deck pallet made exclusively with recycled material (polyolefin flakes) and monitored through the Mould Monitoring Systems, and a mold producing a multiuse container in a 25-second cycle time. This cycle time is the result of an Engel duo 8310/700 speed machine and Haidlmair’s high-end mold, featuring improved cooling and heat equalization. End product warpage is eliminated through a cooling station on which the still-warm parts are placed.

Visitors can see another Haidlmair mold live in action at the Wittmann-Battenfeld stand, producing a reusable, three-component coffee-to-go cup. Hybrid elements are said to be built into the molding plate, which are produced directly in one step using an in-house Lasertec machine. The elements are used, among other things, to optimize cooling and are a combination of conventionally machined mold steel and 3D-printed yellow bronze. Cellmould structural foam technology reduces material use.

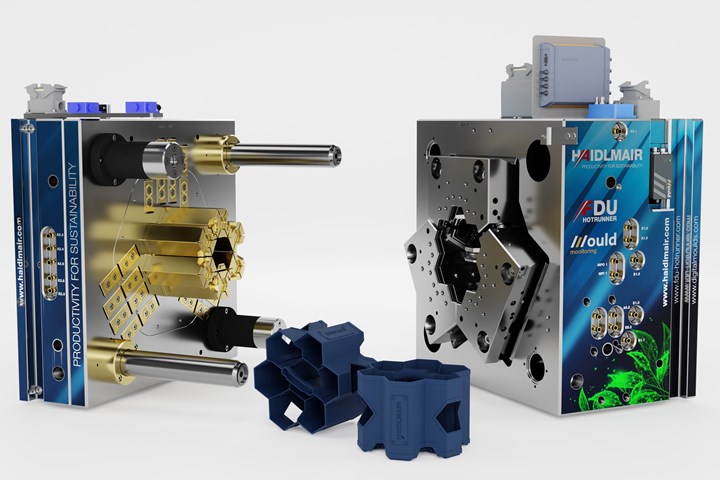

Another mold, the Crinkle Box mini, is highlighted at the Milacron booth, featuring latest-generation FDU SLS nozzle and a compact design. Via an eQ-model machine, together with the iMFLUX process optimizer, Milacron is tackling the challenges of material specification variations. Visitors have the opportunity to have a Crinkle Box made on site, with a choice of materials with highly variable viscosity and different color options.

The K Show runs October 19-26, 2022 in Düsseldorf, Germany.

Related Content

-

MMT CHATS: Navigating Challenges and Innovations in Large-Scale Mold Manufacturing

MSI Mold Builders shares how to overcome large-scale mold-building challenges, sustainability efforts and future technological advancements.

-

Advancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

-

VIDEO: Why Is Sustainability Important to Mold Builders

Marta Orozco with DME shares ways mold builders can be a part of building a more sustainable future.

.jpg;maxWidth=300;quality=90)