Cobot Integration Boosts Repeatable, Reliable Toolroom Production

The ReadyCobot highlighted by FastHeat by Spark Industries enable tool shops and molders to overcome labor shortages, improve quality and lead time, gain scheduling flexibility and reduce costs.

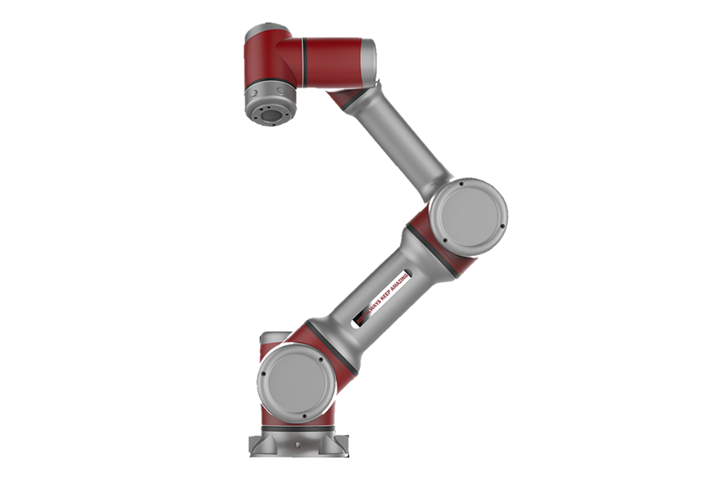

Photo Credit: Fastheat by Spark Industries, ReadyCobot

Fast Heat by Spark Industries is highlighting the ReadyCobot, a collaborative robot solution enabling tool shops and molders to overcome labor shortages, improve quality and lead time, improve flexibility and ultimately reduce costs. Applications that can be performed by the ReadyCobot include assembly; bin picking; palletizing; inspection; machine tending; loading and unloading; drilling, milling, sanding or screw driving; and packaging.

Features include six-axis hand-guided or drag-and-drop programming via the wireless app, up to 39-lb payload, 52" working radius, max speed up to 3.5 m/s, repeatable to ± 0.02 mm, configurable I/O integration and force control natural human-cobot cooperation.

According to an injection molder of caps with seal inserts, they could easily complete a 20,000 product run in 24-hours — three time faster than if it were done manually while reducing scrap by 1-2%. With a constant stream of jobs, the company expected to achieve ROI in six months.

Proof-of-concept videos are created in Elkhart, Indiana, by sister company, Root Industrial and ReadyCobot, a division of long-time automation integrator Tube Form Solutions. For more information, visit ReadyCobot’s webpage.

Related Content

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

.jpg;maxWidth=300;quality=90)