Cloud ERP Scheduling Feature Facilitates Accurate Quoting

Cetec ERP presents the Buffer feature, which ensures ample time is given on a work order, without impacting labor time, estimates or cost.

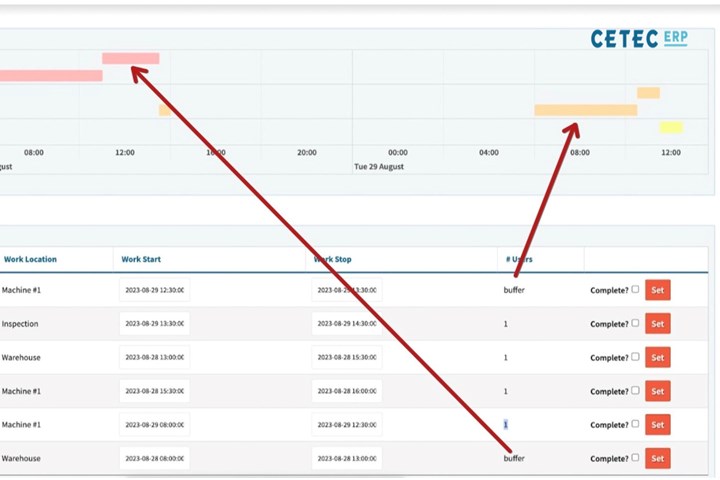

Cetec ERP, providing cloud enterprise resource planning (ERP) software for manufacturers and distributors, has introduced a new scheduling feature that enables users to estimate static buffer time occurring before or after work is completed at a given work location.

For job shops, getting accurate time estimates for work orders helps to drive more accurate quoting, as well as completing jobs on time. Allowing a buffer time before or after a work location/station can ensure ample time is given on the work order, without impacting labor time, estimates or cost, according to the company.

The new field, called “Buffer,” can be managed in two ways: Defaults can be set from a table in the Data Maintenance page named “OrdlineStatus,” or they can be set manually/overridden in a part’s labor plan or order specific labor plan.

Previously, modeling a traveler/router’s schedule to include a buffer period occurring before or after work was completed at a work location took several steps. Users needed to create and utilize a separate “staging” work location, then place that staging work location in the labor plan itself, and finally set the time estimate on that staging location to be a static setup or outsource based time entry in order for the scheduling system to register the buffer.

ERP systems play a pivotal role in the realm of plastic injection mold building, streamlining operations and enhancing overall efficiency. Their ability to consolidate diverse business facets empower businesses to adapt swiftly to changing demands, maintain quality standards and improve cost-effectiveness.

Related Content

-

VIDEO: Perspective on A.I. and Mold Design

Bill Genc of TopSolid shares his perspective on the benefits of and barriers to using artificial intelligence in mold design.

-

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

-

Products and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.