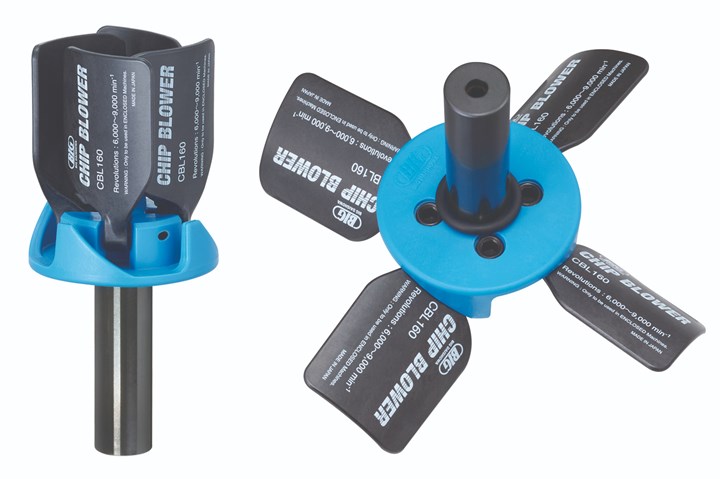

Chip Blower Compatible with Hydraulic and Milling Chucks

The Big Kaiser Chip Blower has an extended steel shank for increased compatibility and can be used with automatic tool changers and programmed into a machining cycle.

Photo Credit: Big Kaiser

Big Kaiser Precision Tooling has updated its Chip Blowers offering, which are designed to make removing chips and coolant from parts and machine tables fast, easy and safe. The new Chip Blower has an extended steel shank, from 1.77" to 2.5", for added compatibility with hydraulic and milling chucks.

The Chip Blower automates in-machine cleaning of coolant and chips by delivering high-volume air flow with spindle rotation. When not in use, the Chip Blower fits easily into any automatic tool change system for vertical, horizontal or multi-tasking machining centers. Big Kaiser says the Chip Blower can be used with automatic tool changers and programmed into a machining cycle, helping to improve machine utilization and increase productivity. The Chip Blower complements the solid construction, fixed blade ChipFan.

The Chip Blower is available with three blade length options and has center-through coolant capability for high-pressure washing.

Related Content

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

.png;maxWidth=300;quality=90)