StackTeck Adds Stack Molds to FastTrackTM Program

The FastTrackTM program is a new approach to fast mold deliveries via automated design, enabling the company to achieve record lead times for round container and lid molds.

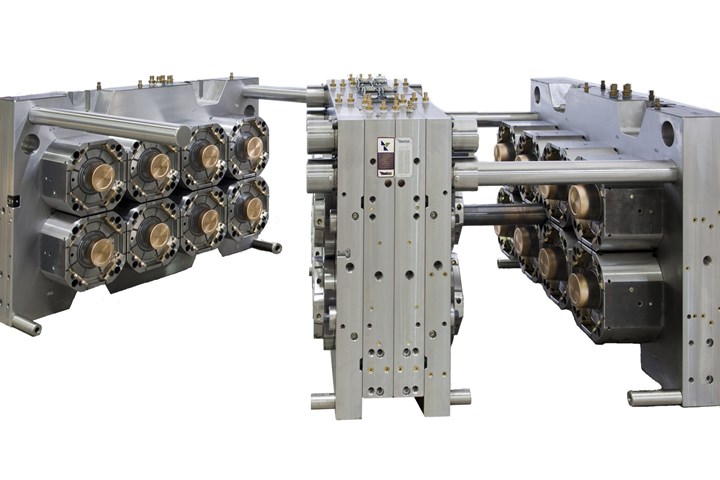

2 x 8 round container mold ready to test in 10 weeks. Image courtesy of StackTeck

StackTeck Systems Ltd., (Brampton, Ontario, Canada) a global manufacturer of multi-cavity, high-volume production molds, has now added stack mold applications to its FastTrackTM program, a new approach to fast mold deliveries, using automated design capabilities that work with a pre-set, optimized set of mold design rules.

The company notes that stack molds for round lids and containers are now available for molds of up to 2 x 16 cavities, making them especially attractive to those companies in need of increased productivity as a response to sudden market demands for food packaging applications.

In recent weeks, StackTeck says it has achieved record lead times for round container and lid molds, with deliveries in the range of 6-9 weeks. The company considers two examples from the FastTrackTM lead time matrix: The lead time for a round container mold in a 2 x 2 configuration is six weeks from order until mold test and at the same time, a 2 x 16 round container mold lead time is now 11 weeks under the FastTrackTM program. Round lid molds also average 6-10 weeks on stack mold configurations starting with 2 x 2 and up to 2 x 16 cavities.

“We understand that our customers need reliable high productivity molds fast to satisfy rising market demands for consumer products, and we have taken all the necessary steps to provide them just that,” says Lou DiMaulo, senior vice president of Manufacturing. “Our team has found the right avenues to compress engineering and manufacturing stages for stack molds, using automated design and product standardization, which in the end translates to huge advantages for our customers.”

.jpg;maxWidth=970;quality=90)