Eden Tool, Eden Manufacturing Supports USA Workforce Tax Credit Act

Rep. Lloyd Smucker introduced the new legislation following a tour of the Pennsylvania-based mold builder’s facilities, highlighting discussions on the importance of exposure, training and education needed in manufacturing.

Representative Lloyd Smucker (PA-11) has announced the introduction of the USA Workforce Tax Credit Act, legislation which will encourage charitable donations for community-based apprenticeship initiatives, career and technical education and workforce development. Eligible nonprofits include educational institutions, community organizations, training institutes, community colleges, scholarship groups and labor union-affiliated nonprofits.

Smucker announced the introduction of the legislation at a press conference, following a tour of Eden Tool Company and Eden Manufacturing Inc. in New Freedom, Pennsylvania.

“The number one issue I hear from small businesses is that they cannot find workers to fill their open jobs. As a small business owner, myself, this was an issue I’ve experienced first-hand and have had to manage through,” Rep. Smucker says. “It’s borne out by the data — the latest release from the Bureau of Labor Statistics reports that there are nearly 11 million jobs available across the country.”

“We know that workforce development programs, and career and technical education programs can help individuals develop the skills needed to find a great career, find that family sustaining job and help them move up the ladder of economic mobility,” Smucker continues. “That’s why I’m introducing the USA Workforce Tax Credit Act, to create more opportunities for individuals to learn the skills that will help them succeed.”

According to Tom Palisin, executive director of the Manufacturers’ Association, the USA Workforce Tax Credit Act introduced by Congressman Smucker “will allow the private sector to invest in the programs and organizations doing the work to develop the future workforce in the trades and manufacturing. Nonprofits need resources to expand their training and education programs, like the Association’s apprenticeship program, and this legislation will allow the private sector to be a part of the skills gap solution by investment in programs that work.”

“A majority of our students need financial aid in order to pursue their dream of earning a certificate or degree,” Pedro Rivera, president of Thaddeus Stevens College of Technology in Lancaster, Pennsylvania, adds. “USA Workforce Tax Credit Act funds will directly impact our students, supporting them as they prepare for in-demand, skilled careers in the trades — and ultimately helping communities here in Pennsylvania and across the nation meet their workforce needs.”

David Tomic, president of Eden Manufacturing Inc. and Eden Tool Company, notes that there are countless opportunities in the tool and die and moldmaking careers which sustain families and have built strong communities. These careers are based on an integrated working and learning model through apprenticeships where a traditional four-year degree is not required. “Both Eden Manufacturing and Eden Tool Company support Congressman Smucker’s federal bill as it mirrors a similar proven State of Pennsylvania bill, and we know that when companies can directly influence where and how their tax dollars are spent, it creates passionate engagement,” Tomic says. “This engagement stimulates a close working relationship between our local manufacturing associations, technical institutions and manufacturing companies to create a scenario where workplace training and development is highly effective.”

Click here to watch the press conference.

Related Content

Unique Mold Design Apprenticeship Using Untapped Resources

To help fill his mold design skills gap, Jeff Mertz of Anova Innovations, is focused on high schools and underprivileged school districts, a school that has lower graduation and college entrance rates. The goal is a student-run enterprise.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreMaking Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreConfronting the Mold Design Talent Drought

Recently, I reposted on LinkedIn the results of an informal survey we conducted, which revealed a shortage of skilled mold designers. It quickly gained a lot of traction. Given the response, I thought I'd summarize the feedback and keep the conversation going.

Read MoreRead Next

MMT Chats: Predictable Manufacturing and Incremental Gains Can Transform Moldmaking

MoldMaking Technology Editorial Director Christina Fuges catches up with the president of Eden Tool and Eden Manufacturing, Dave Tomic. We talk about predictable performance in moldmaking and the value of small incremental gains in an organization versus big change via disruptive technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreMMT Chats: Molding Capabilities Yield New Customers, Team Growth

MoldMaking Technology Editorial Director Christina Fuges chats with Eden Tool and Eden Manufacturing team members to get an update on this mold builder’s move into medical molding, technology investment, team training, Amerimold, and yes, hot rods. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreHard Milling Gives Eden Tool a Competitive Advantage

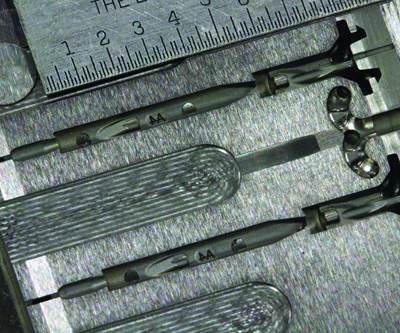

Hard milling proves to be a strategic advantage for a small mold shop that runs lean and serves the medical device market.

Read More

.jpg;maxWidth=300;quality=90)