IMS Software, ModuleWorks, Mastercam Collaborate on G-Code Simulation

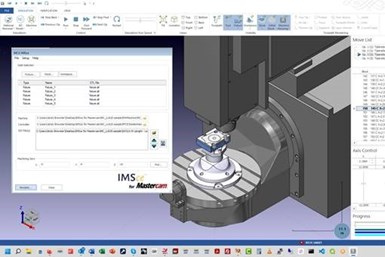

IMS Software, ModuleWorks and Mastercam’s IMSce combines IMS G-code emulation with the ModuleWorks simulation and postprocessing technology to provide a G-code parsing solution that connects directly to Mastercam.

Photo Credit: IMS Software, ModuleWorks, Mastercam

IMS Software, ModuleWorks and Mastercam have collaborated on the development of IMSce for Mastercam. The software solution extends the Mastercam machine simulation with G-code parsing and verification for diverse machine tools and controllers.

IMSce for Mastercam combines IMS G-code emulation with the ModuleWorks simulation and postprocessing technology to provide a G-code parsing solution that connects directly to Mastercam. The solution enables Mastercam users to simulate and verify G-code, including controller variables, subprograms, expressions and canned cycles for a range of machine tools before the workpiece is mounted on the machine.

“There is big demand for G-code simulation and it’s great to see how the technologies of different companies are being combined to create value-adding solutions for the industry,” Julia Meyer-Hendricks, head of business development – digital manufacturing at ModuleWorks, says.

According to Dan Wrenn, president and co-founder at IMS Software, integrated G-code simulation and verification is a major step forward in complex multi-axis machining, improving code quality and dramatically reducing overall programming time versus traditional standalone solutions.

“We are excited to work together with these industry leaders to offer G-code simulation running inside Mastercam for a wide range of machine tools and controls,” Stas Mylek, partnership program manager at Mastercam, says. “As a result, Mastercam users can leverage digital twin technology to simulate and validate their CAM programs, particularly for multi-axis applications, prior to running on their CNC machines.”

Related Content

-

Tolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

Three Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.