Hi-Speed Corp. to Partner with YG-1 Tool Co.

YG-1 says it is excited to welcome Hi-Speed Corp. to its family. YG-1 anticipates that Hi-Speed Corp.’s connections and expertise in the aerospace industry will accelerate the growth of YG-1’s aerospace product line.

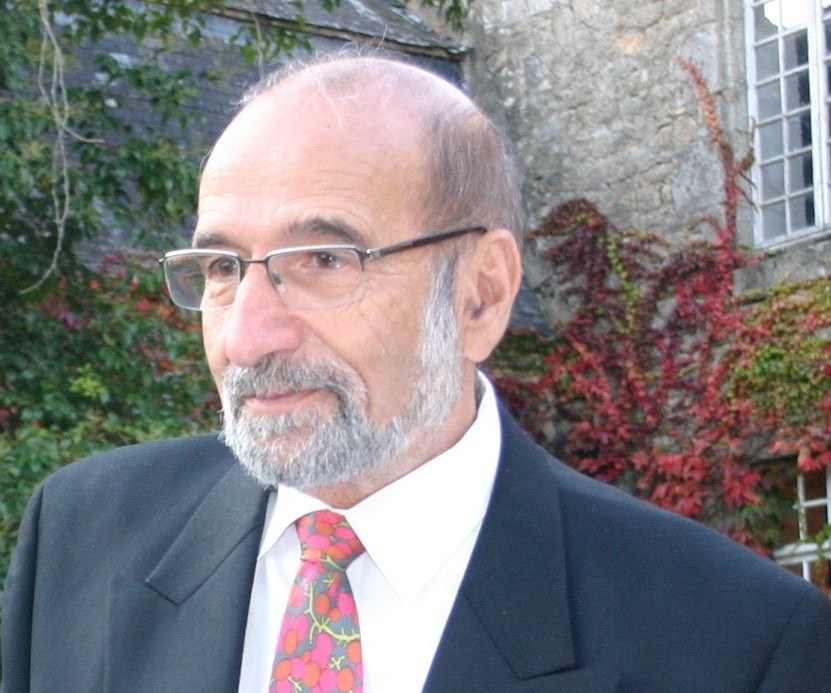

Aerospace veteran, President and founder of Hi-Speed Corp., Jonathan Saada, today announced his decision to represent high-performance tool manufacturer YG-1. This decision comes after representing Widia-Hanita for more than 25 years. According to Mr. Saada, the decision was clear after analyzing the performance, breadth and value of the YG-1 product portfolio.

According to Brian Rabe, CEO of YG-1 North America, YG-1 is excited to welcome Hi-Speed Corp. to its family. YG-1 anticipates that Hi-Speed Corp.’s connections and expertise in the aerospace industry will accelerate the growth of YG-1’s aerospace product line. According to YG-1, the immediate goal is for YG-1 to become a leader in the aerospace industry, in which Hi-Speed Corp. is already a recognized name. The company says that it will work together with Hi-Speed Corp. and its distribution partners to bring value to its customers with its products and services.

YG-1 is based out of South Korea and began 35 years ago when its founder and Chairman, Mr. Hokeun Song, got into business with a few grinding machines in a very small shop. Today, YG-1 has grown to be one of the largest milling, hole making, tapping and turning product manufacturers in the world. It employs 5,000 people with 28 factories worldwide, including manufacturing and distribution facilities in the United States.

Related Content

-

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

.png;maxWidth=300;quality=90)