GWS Tool Group Acquires Indexable Cutting Tools

GWS acquired the Canada-based company, which is reported to be a leader in manufacturing and distribution of ceramic, PCD and CBN inserts.

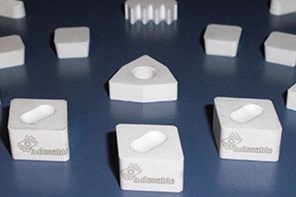

White ceramic inserts for cast iron and high-temperature alloys

GWS Tool Group (Tavares, Florida) has acquired Indexable Cutting Tools Inc. (Ontario, Canada). GWS Tool Group is a U.S.-based, vertically integrated manufacturer of highly engineered custom, standard and modified standard cutting tools. This is the third acquisition in 2021 for GWS Tool Group (including North American Tool Corp., and Taurus Tool & Engineering), and its first international acquisition.

Located in Welland, Ontario Canada and Edmonton, AB, Canada, Indexable is reported to be a technology leader in the manufacturing and distribution of ceramic, PCD and CBN inserts. With six global patents surrounding their microwave sintering processes, Indexable can output ceramic inserts with ultra-fine-grained microstructures that yield increased hardness, toughness, and thermal stability, according to the company. It emphasizes quality, backed by a ISO9001:2015 certification.

“Indexable has a tremendous reputation for producing some of the most innovative and high-quality insert products in the industry,” says Rick McIntyre, GWS CEO. “Its expertise in the areas of ceramic material science is ahead of its time and will undoubtedly bolster our current and future ability to serve the rapidly evolving manufacturing industry.”

“I am very excited for Indexable Cutting Tools to be joining GWS Tool Group,” says John Precious, president of Indexable. “Emphasis on quality and innovative manufacturing techniques is what sets us apart, and, in this and so many other ways, we align completely with GWS’s value proposition. I couldn’t be happier about becoming part of it.”

GWS continues to expand by way of acquisitions and investments in technology, equipment and, most importantly, people, offering what GWS describes as an unmatched value proposition for customers operating in advanced machining environments, especially in the areas of custom round and insert tooling.

Related Content

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

-

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)