Ascend Innovative Mold Launches New Moldmaking Facility to Support North American Manufacturing

Ascend Innovative Mold founders, who have more than 50 years of experience combined, are committed to delivering high-quality tooling solutions to its customers.

Share

Read Next

Ascend Innovative Mold (AIM) is thrilled to announce the opening of its new moldmaking facility, dedicated to providing expert tooling solutions for manufacturing in North America. Founded by industry veterans with a combined experience of over 50 years, AIM is committed to delivering high-quality tooling solutions to its customers.

James Jergens, President of AIM, has been specializing in global tooling in North America and internationally for over 30 years. He has been doing business with his partner, who has been in the industry for over 20 years, mainly serving European customers with high-quality tools made with European materials. Now, they have joined forces to better serve the North American market.

"Our team at AIM operates with a unified purpose and unwavering commitment to our mission statement and core values," says Jergens. "We aim to provide North American plastic injection molders and moldmakers with exceptional support through our global network of team members."

As part of its future plans, AIM intends to purchase multiple mold shops close

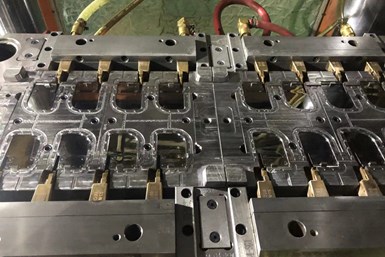

AIM's team is capable of producing molds up to 3300-ton using high-quality equipment from companies like GF Machining and Makino.

to customers and train the next generation of moldmakers. AIM's team delivers new tooling, including full mold builds, hybrid mold builds, and component builds. They also offer tooling modifications, such as engineering changes, repairs, and refurbishments.

With domestic partners in Erie, PA, Dayton, OH, and Greenville, SC, AIM's team also delivers engineering services, including plastics and manufacturing consulting, mold design, and MoldFlow simulation. They use engineering software such as Autodesk Moldflow Insight, NX for mold design, and Catia and Creo.

"Our goal is to be recognized in the industry for our exceptional people, outstanding customer service, and commitment to ethical business practices," adds Jergens. AIM's team is capable of producing molds up to 3300 tons, with automotive and medical tooling as their specialties. They ensure fast delivery and use high-quality equipment like GF and Makino, as well as European steel for key details. They provide North American support by experienced tool engineers.

"At AIM, our core values are people first, ethics and integrity are paramount, our team provides solutions, and we serve the communities we live in," says Jergens. "These are the guiding principles we operate by to support our customers, team members, suppliers, and the communities we live."

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)