Allied Machine Launches Allied Tool Academy

The multilevel, online training program offers access to a range of educational sessions for holemaking and finishing solutions which can be accessed and completed according to the user’s schedule. Newest segment is open for registration.

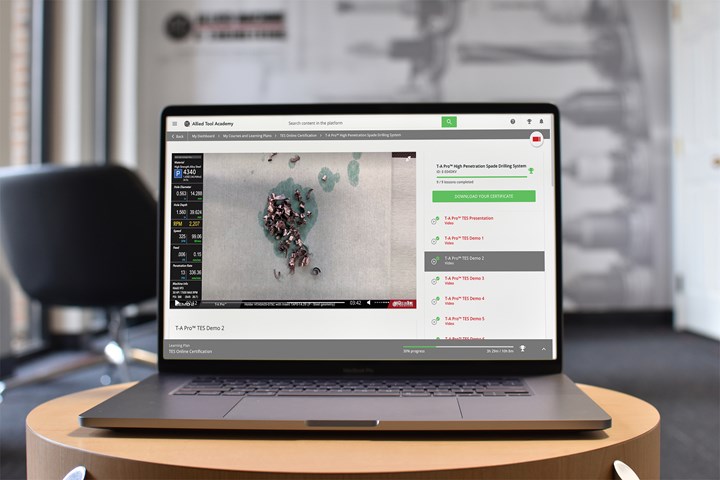

Photo Credit: Allied Machine & Engineering

Allied Machine & Engineering (Dover, Ohio), a manufacturer of holemaking and finishing cutting tools, has launched its newly developed training program, Allied Tool Academy. Within this multilevel program, Allied distributors and end users will be able to register for online training modules, LIVE event broadcasts and onsite Technical Education Seminars (TES). The newest segment of Allied Tool Academy, the online training platform, is now open for registration.

According to the company, while Allied Tool Academy provides the same extensive tooling training included in the three-day, in-person training hosted at the company’s facilities, it can be accessed and completed according to the user’s schedule. Known as TES Online Certification, the 10 courses currently available contain product overviews, demos and short quizzes. As the online platform grows, Allied Machine says additional content will be added such as specific product applications, online tools, distributor utilities and more.

Future plans for Allied Tool Academy include LIVE broadcasts and onsite TES training. Live educational broadcasts will be streamed from Allied’s training facility so that individuals worldwide can gain knowledge on a particular holemaking or finishing application. Further, the in-depth application discussions and practical hands-on training sessions of TES will be offered from Allied Machine’s training facilities once it is safe and appropriate to meet in person.

From basic training for associates to more advanced training for experienced persons in the industry, Allied Tool Academy is meant to meet a variety of needs. According to the company, increased education leads to greater opportunity for Allied products to be applied in the industry correctly and efficiently, and participating in Allied Tool Academy enables individuals to be better equipped in providing optimal holemaking and finishing solutions. Allied’s field sales engineers are available for further on-location training as needed.

“It is our commitment to provide customers with the essential knowledge and skills to be successful in applying our tooling solutions,” shares Kyle Sweitzer, Allied’s training coordinator. As remote learning and virtual spaces become much more prevalent, Allied Tool Academy’s new online training modules are meant to serve as a training tool for individuals unable to travel to Dover, Ohio—individuals seeking education online, on-demand and on their own schedule.

For more details on the Allied Tool Academy, email info@alliedmachine.com or visit www.alliedmachine.com.

Related Content

-

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

.png;maxWidth=300;quality=90)