Thought to Part: Rapid Manufacturing

An example where rapid product development and direct digital manufacturing can work.

What if you were able to walk into a retail store, request a product that does not currently exist and leave with that product? Soon you will.

The Challenge

During the first weeks of December, attendance at theme parks in Orlando, FL, begins to increase rapidly. By the end of the second week it begins to skyrocket. When Universal Studios was faced with an operational issue related to a vendor’s product, turning to direct digital manufacturing (DDM) was their only option.

Jeff Blossey, a design consultant for Universal, was challenged to solve an issue in which finger-print scanners used at the park entrance were not functioning correctly. The anomaly was charged to excessive sunlight entering the scanning window around the edges of a patron’s finger. The result was that when this occurred (on a daily basis), the lines began to backup and cascade well outside the front of the park. After brainstorming sessions, it was decided to design and produce shrouds that would cover the top of the unit, but still allow a finger to fit on the scanner appropriately.

While sketching several options for the design improvement, Jeff and other individuals from Universal realized one significant problem: that they only had about 11 days to design, produce and implement the solution before the line issues would become unmanageable due to the holiday attendance. By the time the design and prototyping would be complete, there would be no time left for most any type of tooling development.

Luckily Jeff had recently heard about rapid prototyping (RP, additive fabrication, layered manufacturing, or DDM when used as the final production medium) on a local news story about an Orlando-based, 3-D design and DDM service provider.

Virtual Prototyping, Phase 1

(3 hours and 30 minutes)

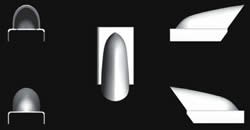

After receiving two different design concepts, 3-D CAD models were produced (see Figure 1). These virtual prototypes were then delivered via e-mail to the customer for buy-off using a free software download (eDrawings) that allows users to open and review designs, as well as take measurements, dynamically rotate views, make notes and use many other design collaboration functions.

Virtual Prototyping, Phase 2

(30 minutes)

Upon review of the 3-D CAD models, Blossey produced comments in eDrawings to adjust the design. Thanks to parametric modeling, where part geometry is driven by variables and relationships versus only fixed numerical values, the required design changes were made in less than 30 minutes. The two modified eDrawings were then e-mailed to Blossey and a final buy-off approval was made.

Physical Prototyping, Phase 1

(3 hours and 20 minutes)

While meeting with the customer originally, several RP processes and materials were presented and discussed. Requirements for prototyping and proto-functional testing were determined to be any plastic-like material, something semi-durable and black in color. Fused deposition modeling (FDM) technology was chosen mainly due to direct use of black, ABS plastic.

Though FDM has a .010" layer thickness, which can lead to a stair-stepped and poor surface finish, it was acceptable for this particular geometry and application. After the prototypes were delivered to Universal Studios, a 3M VHB tape was applied to the mounting surface areas and they were installed and evaluated. The testing period spanned several days in order to gather as much information as possible to drive design changes.

Physical Prototyping, Phase 2

(2 hours and 10 minutes)

As with most all products that exist, originally prototypes go through iterations. One of the two designs used an extended bill at the nose of the shroud to accommodate long fingernails. The other of the two designs made use of an increased surface area at the base for a more secure mounting to the scanner. These two separate aspects were merged together to generate one combined, final design.

This exemplifies a critical success element in rapid product development by which many design options can be easily produced and tested in parallel thanks to parametric CAD design and RP. The result is what is referred to in the design process as fast-failure theory, where final designs arrive faster by failing initial design as quickly as possible. In addition to the composite CAD design, an extended bill was also requested to prevent even more sunlight from breaching the scanning window.

The final CAD work took another 30 minutes to update the model and another hour and 35 minutes to produce the final rapid prototype. After this was delivered and installed within the next day, final design buy-off was achieved and production was authorized. Within 5 minutes, production began.

Direct Digital Manufacturing

(50 production parts, 3 days)

Though concerns of surface finish and durability were initially raised, hopes of using FDM as a DDM process were validated from functional testing results. Show-quality requirements were met with the use the ABS components and no premature part failures were seen during the tens of thousands of cycles per day that were imparted to the prototypes. Therefore in this case RP equaled rapid production.

An FDM machine allowed for 20 units to be produced in parallel, so three successive runs were created to yield the requested 50 production parts over a period of three to four days. As the theme park lines were increasingly growing every additional day, partial production delivery for the first 20 units were provided to accommodate the higher traffic turnstiles (see Figure 2 and Figure 3).

Another unique element of this project is something referred to as on-demand manufacturing or digital inventory, which means that when a customer would like a replacement part or parts, a 3-D CAD file (or RP pre-processed build file) is sent to the additive manufacturing machine with quantity, color, material and finishing requirements. At anytime in the future, Universal could call to request more copies of the shroud and they would be produced on-demand.

What’s the Hold-up?

The case above is a prime example where rapid product development and DDM can work. Though the future of rapid product development and direct digital manufacturing is bright, there are many roadblocks that are slowing its progress. Companies in the industry can very quickly take a concept and turn it into a 3-D CAD model, but the much more significant and slower part of the process comes with evaluation and customer buy-off.

Slow Evaluation and Buy-off Process

Many times we see consensus building and customer approvals taking up to 10 times as long as it took to design and prototype the product, just like it did with the fingerprint scanner shrouds. This is not necessarily bad though, because having customer approval of the product is the most important part. Rushing this aspect could prove deadly to the project’s success. It does say however that speeding up the CAD and RP portion even more than technology already allows for, may not dramatically better the overall project schedule.

One solution is to stress face-to-face customer meetings with the CAD models and rapid prototypes in-hand. So when CAD changes are requested, they are made on the spot (assuming they aren’t too lengthy). This serves to drive a decision versus waiting several days for feedback or final approvals.

Lack of Available 3-D Data

Another element slowing the acceptance of DDM is the lack of available 3-D data and the ease of use to create it. For example, after a package of solar-powered lights for a walkway to the front door of a house was purchased, one of the plastic bases (that looks similar to a miniature tent stake) broke during installation. Within the next day another visit to the hardware store was made to purchase the plastic part, which hundreds of thousands of other people would be wanting as well.

At the store, it was discovered that a customer must buy a single light kit for $19.95 just because they needed the small, black piece of plastic. Making a long story short, it took a lot of Internet searches, a lengthy phone call and seven to 10 days to receive the part via mail. On top of the time wasted and hassle, the part received was incorrect. If customers were able to find and download a 3-D file through the Web, local 3-D printers could allow for products to be produced on-demand at the point-of-sale.

Solving the availability issue of 3-D content will be a significant driving factor in DDM applications. If you do not have a 3-D file, you cannot use RP. Previously it took a lot of expertise to make 3-D files; however, it is getting easier and cheaper everyday. Though most college engineering students today know 3-D CAD modeling by the time they graduate, many of them are entering the workforce into companies that still use 2-D CAD or are just now in the process of converting to 3-D. When the next generation switch takes place, a significant increase will be yielded in 3-D CAD existence and therefore, DDM applications as well.

More people of all ages are starting to learn 3-D modeling and there are various modelers now available for minimal cost, including a program called Cosmic Blobs that allows almost anyone to quickly create organic-shaped 3-D color models (which by the way can be saved in VRML format and directly produced on a 3-D color rapid prototyping system).

Moving from physical parts to digital copies is much easier now too. Recently a 3-D scanner that sells for under $3,000 has been released; an optic, which adds on to a digital camera and directly generates 3-D data is being worked on; in addition to reverse engineering techniques, a customer can also buy data from online companies; and, a 3-D search engine based on design geometry has been developed.

The real key to success in this area will be allowing an average individual to easily find, create and modify 3-D content. Issues also will start to emerge like managing 3-D file content (i.e., adult 3-D content, weapons/firearms, copyright issues, etc.).

Materials Cost

Another item related to the expansion of DDM usage is materials cost. Most RP processes have a cost of about $3 to $10 per cubic inch. Even if a hardware store had its own FDM machine and could directly produce the light component, the part cost would have about $15 to $20 in materials. This means anything over a few cubic inches would undoubtedly be a hard-sell. This goes back to the essence of when to use RP: only select applications that are very low quantity, small, complex and the exact material grade isn’t critical. Spending more money for convenience will most likely be what helps alleviate the high-cost of RP materials.

As the quantity of inexpensive, 3-D printers begins to take over the RP market, it’s important not to overlook their usefulness. Especially when combined with creative post-processing techniques, 3-D printers can prove to be very potent in DDM applications. These inexpensive machines and material costs will be what directly competes with injection-molded components in the future, especially for very small volume and sized plastic components where the price difference per part is small.

A vapor honing process that allows FDM parts to attain an incredible finish similar to glossy, plastic parts purchased at retail locations is available now, and its developer has produced components in this way for several customers.

Alcon has used vapor-honed, black ABS plastic parts for an end-use part on one of their medical systems. By painting or metal-plating with chrome, nickel and other alloys, relatively inexpensive RP parts can be made to appear very high-end, and therefore increase viability of selling it as end-use.

Summary

The most important factor in considering DDM versus conventional tooling is targeting applications with small, complex geometry. Many also would say that it must be a low-quantity application. However even if it’s not the ideal DDM application, there is still a significant value to being able to start production immediately. Though advancements in high-speed CNC machining software and hardware have come a long way, the majority of toolmakers spend at least a few weeks before yielding initial prototype or bridge tooling components. The production companies that will be successful in the future will be those that not only integrate RP into the design process, but also use it for at least initial production runs.

Everywhere we look customization is getting more popular. Up to this point, it has been mainly focused on colors (e.g., design your own shoes), graphic designs (cellphone covers in the mall and corporate gifts), and text-based manipulation (trophy shops). However, very soon we will see a trend of 3-D customization focused on shape and form-styling. Additive manufacturing will be the enabling technology for this revolution. Look for possibilities not only to integrate RP into the upstream design process ahead of tooling, but also its potential to combine it into direct or hybrid tooling.

So be ready for the one-hour proto versus one-hour photo. Be ready to help design and customize your own consumer products, industrial equipment and even toys. Be ready to walk into a 3-D printing services company near your home with a broken part and walk out with a 3-D copy. This is when companies and individuals alike will be able to easily move in 3-D from the physical world to the digital world and back again. This is when you, the engineer, toolmaker, accountant, lawyer, doctor or student, will begin to design, produce and purchase all at the same time.

Related Content

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreRead Next

The Impact of Rapid Prototyping On the Plastics Industry

Examining the level of acceptance and use of additive fabrication technology in the development of injection molded components.

Read MoreDirect Metal Laser Sintering and Tooling

The applications, benefits and limitations of direct metal laser sintering for mold manufacture.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)