Women Owners See Data as Growth Strategy for Moldmaking

Report suggests that women will own one-third of North American mold builders by 2030 and will use Industry 4.0 to grow their businesses.

A shift is happening in mold manufacturing. This traditionally and predominantly male-owned industry sector will see more female ownership over the next decade. The Manufacturing Institute, APICS, and Deloitte surveyed more than 600 women in manufacturing and conducted nearly 20 manufacturing executive interviews to explore how effectively manufacturing companies are attracting, recruiting, and retaining women, as well as how to close the gender gap. The women surveyed were well-educated (90 percent hold a bachelor’s degree or above), experienced (71 percent have been working over 15 years), and hold senior positions.

Many of these talented women are employed by large companies (52 percent work in organizations with annual revenue over $1 billion). This last data point disproportionately weights the data toward large manufacturers, which, according to the Bureau of Labor Statistics only represents 11 percent of the total GDP of the sector in the United States. Smaller manufacturers ($2M - $20M) represent more than 75 percent of the financial contribution to the economy. It is in these smaller industrial firms where women will become more powerful owners during this new decade.

It is in smaller industrial firms where women will become the most powerful as new owners during this new decade.

The Female Force

Women represent a vast talent pool and constitute one of U.S. manufacturing’s largest pools of untapped talent. Women totaled about 47 percent of the U.S. labor force in 2016, but only 29 percent of the manufacturing workforce within plant floor positions. Senior management and ownership are significantly lower.

More data reveals that women are earning more than half of all associate’s, bachelor’s, and master’s degrees, and are advancing in their careers, holding more than half of all U.S. managerial and professional positions.

These powerful and capable women are now in their mid-30s to late 50s and have made millions for their employers. Earning levels have capped out and only business ownership will allow these women to take charge of their careers and financial trajectory.

The traditional network in manufacturing is seeking an exit strategy. These men (60 to 80 years old) are ready to retire or face health challenges necessitating a departure. None wish to have a “fire sale” and get peanuts for a successful manufacturing business built over decades. Enter successful MBA-holding women who realize that sales, marketing, business development, and technology (particularly customer experience online) can grow well-established manufacturing firms with their expertise.

Accelerated Manufacturing Brokers is aligning powerful women with the extraordinary manufacturing business acquisition opportunities. Women entrepreneurs have first-hand knowledge that gender diversity benefits an organization through an improved ability to innovate, generate a higher return on equity, and increase profitability. These new women entrepreneurs are committed to significant growth and understand that when employees experience an organization committed to inclusion, innovation, and profitability follow.

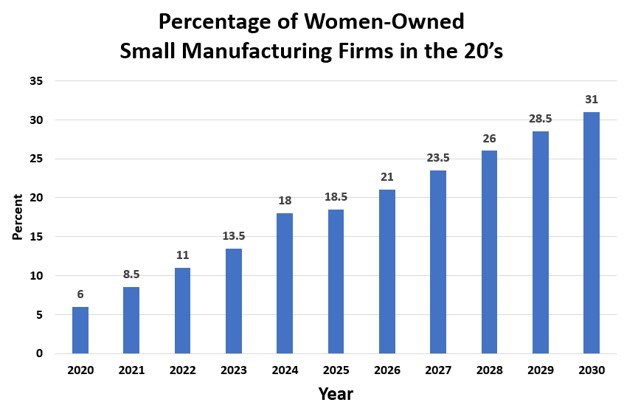

The data of women-owned manufacturing companies are not precise; however approximately 6% of privately-held manufacturing companies (with $2M - $20M in annual revenue) were owned by women by the beginning of 2020. Accelerated Manufacturing Brokers will be tracking this metric throughout the ’20s. With a 2.5 percent increase in female ownership each year for the next decade, nearly one in three manufacturing firms will be owned by a woman by 2030. Graph courtesy of © 2020 Accelerated Manufacturing Brokers.

Wise Women Focus on IIoT for Growth

As stated earlier, many women are earning MBAs and many of these professional women are also very familiar with IIoT (Industrial Internet of Things), which is critical to the future of mold manufacturing. Herein lies the plan for growth, as seen by many women owners who are willing and able to buy a $2M moldmaking firm and grow it to $20M+.

IIoT is needed whether a small or mid-sized moldmaker wants to be efficient or prepare for the best price and be acquired. When prospective buyers see that a moldmaker is using IIoT to connect hardware and software on the shop floor, it is obvious that the manufacturer is increasing all aspects of productivity. From proper documentation to communication throughout the production process, using IIoT is the leading indicator of an advanced operation.

IIoT in moldmaking is a necessary process because bringing a product to market usually consists of a program manager, a mold designer, a machinist, and a plastics engineer who must all work together cohesively. One area that applies IIoT on the shop floor is machine monitoring, and moldmaking is an industry where monitoring OEE (Overall Equipment Effectiveness) is crucial.

Specifically, the program manager needs to make sure parts are of good quality and get to the customers on time, while the plastics engineer and CNC machinist both rely on machines being used to their full capacity promptly. When real-time updates display on monitors and computers across the shop floor via this software, it keeps everyone current on any snags in the process.

IIot documentation is critical — all team members in engineering and on the production floor benefit from complying with documentation standards. For example, keeping proper documentation with products such as PDM (production data management) helps maintain ISO standards, streamlines the quality assurance process, ensures revision control, and better yet, helps a mold builder’ shop floor go paperless. Keeping good documentation also helps with audits and overall organization.

Female owners report that IIoT documentation is part of cohesive team building and future growth.

Accelerated Manufacturing Brokers, Inc.

(908) 387-1000

acceleratedmfgbrokers.com/sellers/

Frances Brunelle, founder.

Fran specializes in the sale of lower middle-market manufacturing companies nationally. Additionally, she hosts the WAM Podcast (Woman and Manufacturing), which highlights and profiles the opportunities for women in senior management and ownership positions. Fran and her team help to ensure the continuity of U.S. Manufacturing by transitioning ownership to the next generation of entrepreneurs. Fran writes on topics that help manufacturing business owners prepare their companies for sale and navigate the sale process to ensure a positive financial result in support of their retirement. Fran was recently named to 2020 Most Influential Women in Mid-Market M&A in Mergers & Acquisitions publication.

Related Content

The Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreMMT Chats: Solving Schedule and Capacity Challenges With ERP

For this MMT Chat, my guests hail from Omega Tool of Menomonee Falls, Wisconsin, who share their journey with using enterprise resource planning (ERP)—and their people—to solve their schedule and capacity load monitoring challenges.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreThe Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More