What’s Your HR Pain Point?

Members of the American Mold Builders Association (AMBA) gathered together last week in a breakout session geared toward helping them bridge their HR “pain points” by sharing experiences and solutions.

Members of the American Mold Builders Association (AMBA) gathered together last week in a breakout session geared toward helping them bridge their human resources “pain points” by sharing experiences and solutions. The breakout session, which was held during the AMBA’s annual conference in Cleveland, Ohio, sprouted many great ideas that I will share here.

More than just a band-aid to cover over looming HR issues, these ideas are current, viable solutions that any company can use to “heal” those open HR lesions.

The discussion was led by James Murphy, a consultant with Harbour Results Inc. The group addressed a variety of HR-related topics and following is the overall summary of solutions the group created (with thanks to Mr. Murphy for taking great notes during the session and sharing them with participants).

Issue: Hiring and Talent Acquisition

Solutions:

- Work with local high schools, vocational technical schools, community colleges and career centers to locate younger talent. KEY: Develop relationships with the people who run and organize these institutions to gain “insider intel” for identifying which people the shop should focus its recruiting efforts on.

- Conduct plant tours on a quarterly basis. This offers young people an opportunity to see what mold manufacturers do. KEY: Having parents come along also provides the shop with an additional (possible) advocate.

- Offer short-term internships or co-op programs that give students a rotational experience within the shop to see and learn about engineering, machining, and mold building. These programs can be organized to occur only a couple hours per week to avoid too much disruption but still make an impact.

- Become an active member of state and local organizations, like AMBA, that focus on human resources and manufacturing. KEY: This leads to better shop recognition and opportunities.

- Use various social media, such as Indeed, LinkedIn, Monster and Workable. KEY: Today’s millennials live online. Going social allows shops to get their messages out to a much broader audience.

- Create a referral program for current employees to incentivize them to recommend a friend or colleague to join the team. KEY: If the new hire successfully completes his or her probationary period, the referring employee would receive a “finder’s fee” set by the company. Your shop gains a new, promising hire and current team members get a little extra cash—It’s a win-win.

Issue: Effective Training and Development

Solutions:

- Develop an internal apprenticeship program that lasts between two and four years. KEY: Include “milestones” for each training segment where mentors must sign off on skills learned before moving to the next segment.

- Hire an external consulting firm, such as Praeco Skills LLC, that can assist in the development of an effective apprentice training curriculum. KEY: If your current program needs updating or you are having a hard time figuring out where to begin designing a program, a consultant can help. What’s your time worth? Short of using a consultant, revert back to the suggestion about getting actively involved with an organization that can provide proven methodologies and fellow members who use them.

- Conduct semi-annual reviews with employees at all levels. KEY: It’s a good way to stay in front of employee concerns and developmental opportunities. However, there is typically some training required along the way for managers delivering this feedback.

- Online learning via videos and webinars is being used with increased frequency. KEY: For topics not requiring hands-on activities to learn, webinars and videos can be very cost effective and offer the ease of accessibility from the shop floor or conference room.

- Conduct 360 management-review sessions annually. KEY: These reviews give employees an opportunity to provide feedback on their managers, which, if used as a continuous improvement tool, can build morale and strengthen teams.

There also was a lot of discussion about the issue of training people only to lose them afterwards to higher-paying companies. The group tossed around the concept of having apprentices pay a portion of their training in addition to having them sign work agreements after completing their training programs. This is an interesting concept, and I know that there are companies in Canada that require apprentices to pay half of their training fees. The apprentices can earn half of their investment back once they have completed in-house training and by earning a minimum grade-point average as determined by the employer. Are any U.S. shops doing this? If you are, please share your system.

Issue: Compensation and Benefits

Solutions:

- AMBA members agreed that one of the best and easiest ways for managers to benchmark wages and benefits is by using the AMBA’s annual survey in quarter 4. KEY: Understanding what the U.S. mold manufacturing market is paying for talent is a great way to retain top employees.

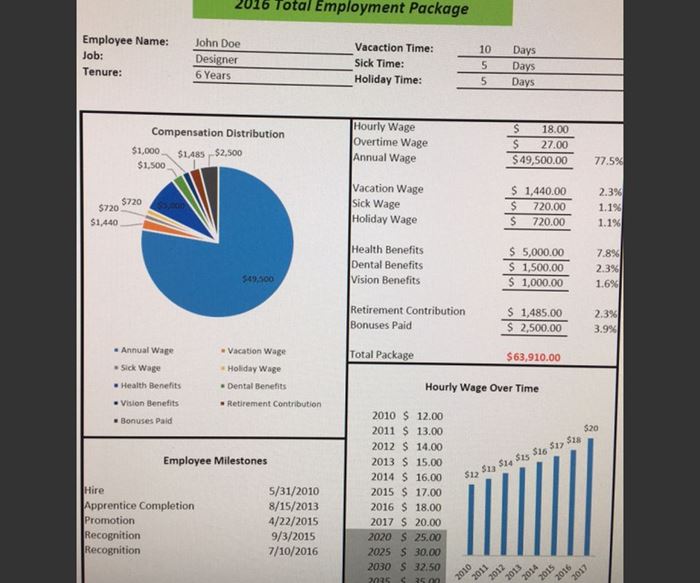

- Have a “total compensation” discussion with employees annually, or provide an annual, customized report for each employee that includes benefits and vacation time. KEY: Providing comprehensive details about compensation is crucial for getting employees to understand how much the company actually pays, or invests, in them.

- Healthcare costs is no new concern; however, it is becoming a major factor for employees as they decide where to work when there are options. Health, vision and dental are very expensive to cover for employees and benefit models that include stipends for personal use are becoming more popular and more widely available.

Issue: Health and Safety

Solutions:

- Require annual employee health screenings covered by the company. These screenings typically include a physical, shots, and other preventative health procedures. KEY: Company-sponsored screenings are a great way to keep employees healthy and, in turn, can help reduce the cost of insurance coverage. Consider bringing a local healthcare team on-site for convenience.

- Add healthy food and drink options to the workplace. Some companies provide baskets of fresh fruit, as well as fruit juices, granola bars, nuts and other tasty options. KEY: It is a relatively inexpensive way to help employees engage in healthier eating habits, plus it can help boost morale.

- Having regularly scheduled safety meetings, perhaps monthly, creates an avenue for employees to bring issues to the attention of management in a constructive manner. KEY: Not only does this promote safety in the workplace, but it also serves companies well should OSHA come knocking.

This group session covered a lot of ground, but they took the discussion a step further by also discussing how their companies could give back to their communities and as a result, strengthen the fiber of their company cultures. Here are the solutions they offered:

- Encourage community service, such as food sorting at a food bank, helping at the Humane Society, participating with Habitat for Humanity and more. KEY: These suggestions are just the tip of the iceberg of ideas for team building and volunteer opportunities that shops can sponsor.

Having worked for a company that does an awful lot of giving back to its community and to those where its employees live, I can attest to the effectiveness of this kind of program. There was a lot of bonding over common causes and always someone willing to help out. You learn so much more about the people with whom you spend every working day.

- Hold monthly or quarterly ‘town hall meetings’ led by the management team. KEY: This is a way for various departments to share important information and speak to the short- and long-term health of the company. It’s another great team-building exercise and is often very motivational because employees want their companies to succeed.

There are probably more great ideas to be shared out there. If you have some that you have used, or that were used by an employer, and it was successful, I hope you’ll email me and tell me about it.

Related Content

Eden Tool and Eden Manufacturing: A Story of Resilience, Growth and Innovation

This critical parts manufacturer, founded on solid tooling fundamentals, didn’t get derailed with the unexpected passing of the owner because leadership was already building a solid business, not just a good tool shop. Here’s how they managed change incrementally… and they’re not finished yet.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)