It is not possible to establish fixed rules when it comes to choosing the right machine tool. However, attuning to the needs of shops and delivering on the promise to ensure machine availability as much as possible are often said to be the most important factors that drive moldmakers to opt for a certain machining center or machine-tool brand, no matter the initial price tag. I talked to some European mold shops to find out why.

Uptime, Location and Reputation

Moldmaker Schweiger Formenbau in Uffing, Germany, specializes in automotive work, creating highly sophisticated molds that are used in premium vehicles. For example, the company builds two-component injection molds that make headlight end plates. These customers place high demands on the end products and do not accept the slightest blemish. Accordingly, the injection molds have to meet similar requirements. As a rule, surfaces must be as smooth as glass and the company must maintain tolerances of less than 0.02 millimeter.

For Managing Director Anton Schweiger and his team of approximately 75 employees, this means meeting the highest standards of precision and quality with every injection mold that Schweiger Formenbau produces. Additionally, the company is competing in a global market, which—among other things—is subject to enormous pressure regarding costs.

However, facing the strain of global competition, the qualified toolmaker and his team have adjusted and positioned themselves. The team relies on an automated process chain that ensures absolute security and ends with injection molds that meet all requirements. In 2016, the company built a new production hall and invested in two DMC 210U and 270U five-axis machining centers from DMG MORI.

“We knew that the machines had to run at least 6,500 hours per year. This machine uptime was essential for us since it is a large investment and our customers count on us,” Schweiger says. “When making a selection of machine tools, production capacity, cutting accuracy, cost of the equipment and its reliability and performance are major considerations. However, the availability of replacement parts and factory service and support are very important criteria when considering the appropriate machine type and manufacturer.”

Schweiger machines many large injection molds automatically in one setup, machining 40 to 50 hours and sometimes as long as 100 hours non-stop. One of Schweiger's main focus areas is milling large, complex molds that weigh up to 9 tons. The cavities are often very deep. They typically are between 300 and 400 millimeters deep and are sometimes as much as 500 or 600 millimeters deep.

Equipped with appropriate pallet automation, the machines run around the clock, seven days a week with one-person shifts. On the weekends, the machines run completely unmanned. This requires the highest process reliability across all relevant components and functions.

DMG MORI and Schweiger Formenbau are both based in Bavaria, Southern Germany. For Schweiger, his company’s proximity to the machine-tool builder and the completeness and availability of the builder’s stock of repair parts were important factors when buying the two large machining centers, which was a significant investment for the medium-sized, family-owned business. “The DMG MORI machines were certainly not the least expensive ones,” Schweiger says. “But, in relative terms, the initial machine price is not what counts. What counts is machine availability, reliability, productivity and support in application engineering.”

“The initial machine price is not what counts. What counts is machine availability, reliability, productivity and support in application engineering.”

Sometimes, a “subjective” evaluation is more important than the objective process. A subjective evaluation takes into account requirements such as tool capacity, work envelope, horsepower, control type, compatibility with existing equipment and the number of available machining axes.

On top of that, certain machine tools just have a feel, a reputation and a company structure with which people are comfortable. “We have to feel comfortable with the company and the people with whom we are working,” Schweiger says. “Our company and our machine-tool provider need to be on a level playing field.”

Shared Experience, Service and Lifecycle

This subjective evaluation was a starting point for Hans-Jürgen Koppolt, production manager at Deckerform Production Systems (Deckerform) in Aichach, Germany, as well when he was looking to increase production capacity by investing in larger machining centers capable of five-sided complete machining. “We often talk to other mold shops and toolmakers, and many of them are friends rather than competitors,” he says. “So, when it comes to investing in new equipment, we listen to other shops describe their experiences and then start our own research.”

For instance, the company has invested in a BFR23 five-axis machining center made by Swiss machine-tool maker Reiden—not one of the most known brands. “The machine is ideal for extreme cutting forces and roughing operations with its box-type guideways.” The machine can rotate and machine workpieces with a diameter of 2,100 millimeters while the machine housing is completely closed. The compensation of the physical deflection of the beam is electric-hydraulic controlled for precise movement of the Y axis.

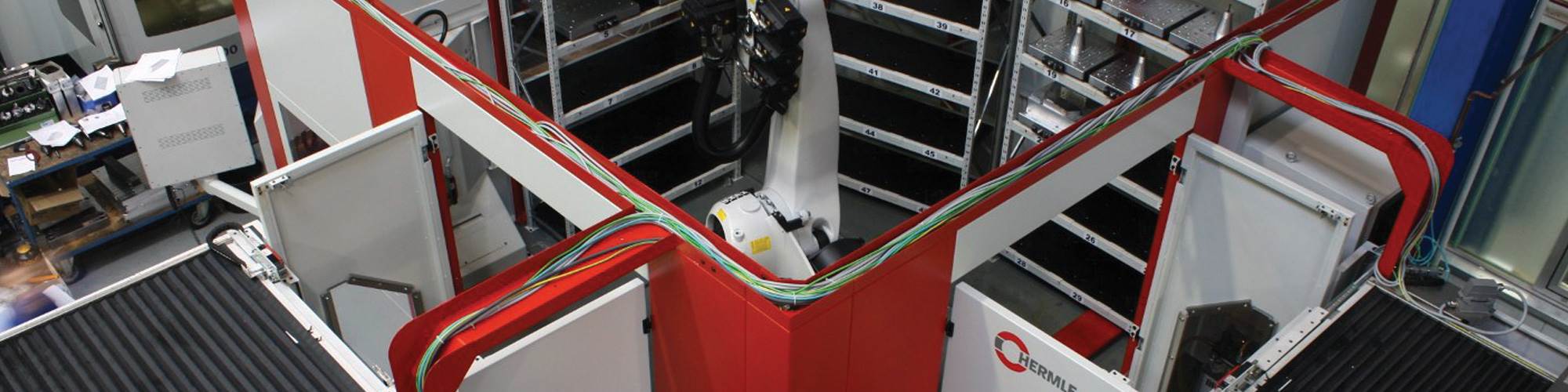

Deckerform’s decision to invest further in two large machines, the C40 and C50 U five-axis machining centers from Hermle Machine Co. (Hermle), resulted from Deckerform’s positive experience with its first Hermle machine, a C30 U. “Our operators are used to the Hermle machine and the CNC machine,” Koppolt says. “Investing in the same brand makes it easier to have new machines up and running. But, the most compelling reason to decide for another two Hermles was axis travels, spindle speeds and flexibility since we have high-mix, low-volume production.”

Stephan Kegelmann, managing director at Kegelmann Technik near Frankfurt, Germany, cites similar reasons when asked which are the most important criteria in selecting a machine tool. “It’s important to be taken seriously as a customer,” Kegelmann says. Since 1992, the tool and moldmaker, who specializes in 3D printing, prototyping, modelmaking and the manufacturing of end products, has counted on Hermle milling machines to machine its molds, tools and parts. Kegelmann Technik has always been a partner for Hermle, rather than just a customer.

“We have always pushed Hermle when we had a new idea and wanted to try something new,” Kegelmann says. “In 1998, for example, we suggested that Hermle get rid of the traditional t-slot tables and introduce zero-point clamping systems, which was something new at the time. Hermle always has been open to new ideas, and we often help them develop additional features and machine improvements. The working relationship between our companies is excellent.”

Recently, Kegelmann Technik rebuilt a whole automated cell with Evomecs, a modular-built, browser-based, integrated automation system for single-part and small-series production. “This cell integration was a first for Hermle, but we never had any problems. Hermle is a family business just like many of its small to medium-sized customers. There is a lot of trust and confidence,” Kegelmann says. As a result, Kegelmann Technik operates six Hermle five-axis machining centers, and all of them are automated and arranged in machining cells where a robot handles blanks and pallets for unmanned operation.

Kegelmann believes that Hermle is the only option when it comes to milling, even if Hermle’s machines come at a higher price tag than others. He says, “Our approach here is to stay on the leading edge of machining and manufacturing technologies.” He says that Kegelmann Technik examines what the equipment costs over the span of its entire life and not just its initial cost. That includes expenses for maintenance, service and spare parts. “The more reliable a machine tool is, the less you spend on maintenance and service. However, if you need help, a machine-tool builder who builds reliable machines that rarely need unscheduled service can react quickly. That’s important. No company can afford long machine downtimes.”

About the Author

Barbara Schulz

Barbara Schulz is Gardner Business Media’s European correspondent. She can be reached at bschulz@gardnerweb.com.

Related Content

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More