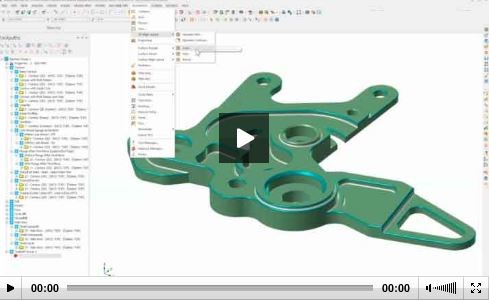

Video: Toolpaths Boost Roughing Efficiency

Cutting cycle times in half is just one of many benefits this shop realized from a previously unexplored feature of its CAM software.

In the video above, staffers at Accede Mold & Tool detail their experience with Dynamic Motion, a type of Mastercam toolpath that relies on intelligence in the software to access an extensive data set and then “decide” on the most efficient cutting motions possible for the specific part. According to the developer, the software takes into account not only the area to be machined, but also material conditions that change throughout the cut. For Accede, this translates to an approximately 50-percent reduction in roughing cycle times, reduced cutting tool costs, reduced heat in hardened materials, less stress on cutters and machines, improved programming productivity, and smoother, more reliable machining.

Essentially the same story, along with a few other tidbits, is told in this case study.

.jpg;maxWidth=300;quality=90)