VIDEO: Quick-Change for the Entire Mold Assembly

As opposed to just core and cavity plates, this quick-change system is designed to streamline changeovers of entire molds, including different-size tooling.

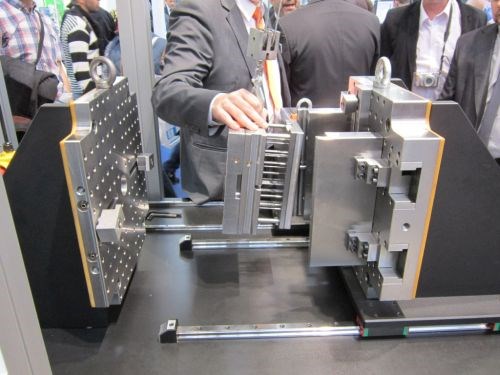

Taken at the Euromold show in late November, the above video depicts Wade Hopewell, a UK-based technical sales engineer at mold component supplier HASCO, demonstrating the operation of the company’s quick-mold-change system. Designed for low-volume production, it combines the company’s own K3600 small-series mold (consisting of molding plates, the ejector assembly and all associated components) with the Clever Mold System (CMS) from B&R GmbH.

According to the company, the primary difference between this configuration and other quick-change systems is the fact that users change not just core/cavity inserts, but the entire mold assembly. The clamping jaws on the ejector side of the CMS can be adjusted as-needed with a handwheel to accommodate different-size molds, which are further secured by couplings and clamping devices. Keeping the CMS mounted in the press and securing different-size molds without the need for screws or bolts is said to significantly speed job changeovers. Additionally, purchasing multiple K3600s from stock is said to be more cost-effective than producing new molds from scratch.

This system is just one of many examples of technology that intrigued me at the Euromold show. As in recent years, additive manufacturing proved a particularly big draw, with an entire hall dedicated to that technology drawing plenty of traffic day-in and day-out. Yet, the show also offered plenty of innovations from more traditional players in the die and mold industry. Click through this picture gallery for a sampling of what caught my eye.

.jpg;maxWidth=300;quality=90)