Video: Printed Molds Slash Development Costs, Lead Time

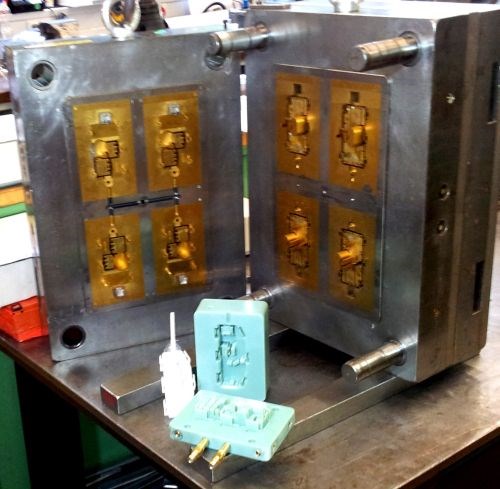

When testing prototype injection-molding parts reveals the need for design changes, this manufacturer realizes significant savings by printing new tooling rather than machining it.

Although much of the buzz surrounding additive manufacturing involves its rising potential for end-use production parts, the technology's long-standing advantages for prototyping continue to attract manufacturers into the fold. One of the latest companies to come on board is Robert Seuffer, a German manufacturer that uses 3D printers from Stratasys to dramatically reduce the time and cost of producing injection-molded sample parts.

Stratasys detailed the company’s story in a recent press release, as well as the video above. Seuffer specializes in plastic parts for household appliances and commercial vehicles. Prior to mass production, injection molded parts require testing for performance and fit, often in environments involving moving mechanical parts and high temperatures. Historically, part design changes have required corresponding alterations to the metal injection mold tooling, a scenario that typically involves costly and time-consuming machining work.

Today, that's no longer the case, says Andreas Buchholz, head of research and development at Seuffer. "With Stratasys 3D printing, we can design the first drafts of the injection mold within a few days and 3D print them in less than 24 hours for part evaluation. Traditionally, it would take eight weeks to manufacture the tool in metal using the conventional CNC process. And while the conventional tool costs us about 40,000 euros, the 3D-printed tool is less than 1,000 euros, a saving of 97 percent."

The company also produces 3D-printed molds for its hot melt process. These molds, which are used to overmold low-melting-point polyamide over electronic circuit boards, are created with Stratasys' rigid, opaque Vero materials.

"More and more manufacturers are adopting 3D-printed tools as a complementary injection molding solution--not only to cost-effectively test products before mass production, but also to produce customized parts," says Andy Middleton, General Manager, Stratasys EMEA at Stratasys.

For more content from Stratasys about 3D printing in injection mold applications, click here.

Related Content

-

Making Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

-

MMT Chats: The Connection Between Additive Manufacturing Education and ROI

This MMT Chat continues the conversation with Action Mold and Machining, as two members of the Additive Manufacturing team dig a little deeper into AM education, AM’s return on investment and the facility and equipment requirements to implement AM properly.

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)