VIDEO: New Process Speeds Time to Market

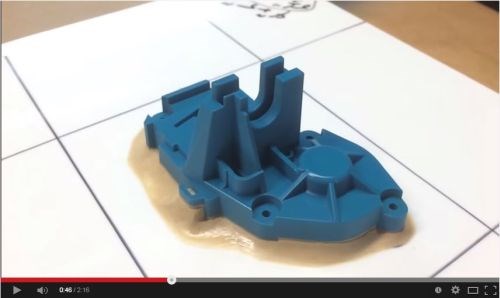

Precise, 3D-printed wax pattern masters can significantly speed the prototyping process.

The above video details a new process that leverages high-precision 3D printing to take weeks off the process of developing plastic or metal prototypes.

The process is the result of collaboration between Solidscape, a subsidiary of Stratasys and a manufacturer of 3D printers, and LSR’s Design Studio, a wireless product development company. The former company’s equipment prints at a resolution of 5,000 dots per inch (DPI) to produce highly precise wax masters. LSR produces silicone molds directly from the wax masters—no finishing required—and then builds casts from the silicone molds.

More details on the applications shown in the video are available on Solidscape’s web site.

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)