USA or Bust? Not for this Mold Manufacturer

Since its founding in 2010, this company has leveraged a balanced approach to sourcing tooling from overseas—one that has facilitated significant growth in its operations here at home.

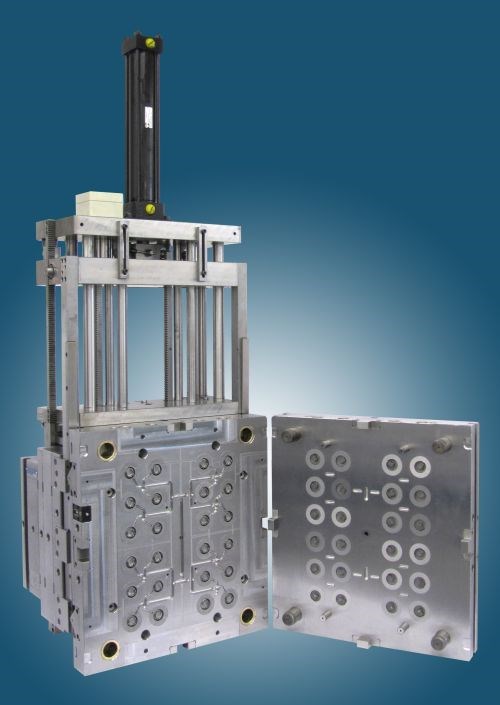

Burteck specializes in complex tooling like this unscrewing mold. The company takes great care to hold all tooling carrying its name to the same high standard, regardless of where it's made.

I can envision certain industry folk I know turning up their noses upon hearing about a mold maker that sources approximately 60 percent of its work from China. I had the same reaction upon hearing that statistic, but I try not to judge without all the facts. As it turned out, the more I learned, the more the company’s approach made sense.

The moldmaker in question, Burteck LLC, is relatively new in the market. Founded in 2010, it has grown rapidly, largely based on what program manager John Eastham calls a “balanced” approach to global production. That rapid growth, in turn, has resulted in a dramatic expansion of the company’s U.S.-based operation in Connecticut, a fully-outfitted mold shop that provides gainful employment for 18 people and handles an increasing share of the company’s overall production. Eastham fully expects Burteck to continue that growth—and, along with it, the company’s contributions to the U.S. economy and manufacturing base. “The philosophy of ‘USA or bust’ is a very narrow-minded point of view,” he says.

Our February-issue profile tells the shop’s story.

Related Content

-

MMT Chats: 5 in 5 with Best Tool and Engineering

MoldMaking Technology Editorial Director Christina Fuges reveals 5 best practices for improving efficiencies within shops...in 5 minutes. Our guest is Joe Cherluck, President of Best Tool and Engineering in Clinton Township, Michigan.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

The Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

.jpg;maxWidth=300;quality=90)