Total MoldMaking Business Index for September 2013

48.2

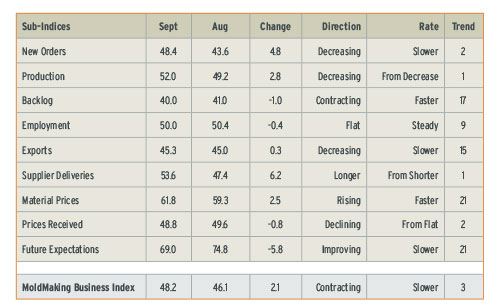

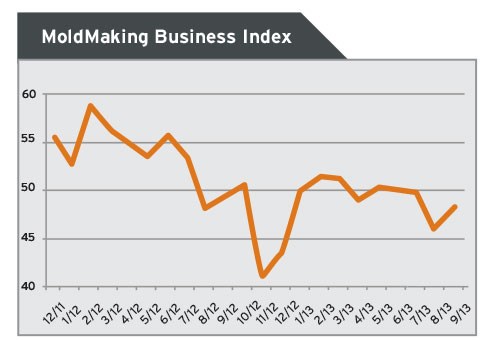

Our latest survey of the North American moldmaking industry indicates that overall activity levels declined for the third straight month in September when compared with the previous month, but the rate of decline is decelerating. The MoldMaking Business Index for September 2013 is 48.2 (a value less than 50.0 indicates a decrease in business levels for the month). The latest index value is a 3.5-point increase from the August value of 46.1, and it is a 0.9-point decrease from the 49.1 value posted in September 2012.

The index recovered much of the deeper drop-off from last month, but not all of it. If we look at the bigger picture, the overall trend all year for the MoldMaking Business Index has been flat-to-down, and the September reading continued this trend.

Yet again, there is some consolation in the fact that the latest reading for our MoldMaking Business Index is a contrast to many of the major indicators that measure overall manufacturing levels in the U.S. The ISM Manufacturing Index in September posted its highest mark since 2011, coming in at a heartening 56.2. Demand for autos remained strong in September. The upward trends in residential construction and real estate data decelerated a bit recently, but both are still quite strong when compared with last year.

The biggest threat to the current economic recovery does not come from any of the economic fundamentals at the present time, but rather from Congress. As I write this, the Federal government is in shutdown, and a vote on the nation’s debt ceiling is just a few days away. If these two issues are not resolved in an expeditious and somewhat graceful manner, the effects on the U.S. economy will be dire. If, on the other hand, Congress and the President can quickly get us past this debacle, then the pace of economic expansion will accelerate through at least the end of 2014.

Taking a closer look at the categories that comprise our index, the new orders component was 48.4 in the latest month. This is significantly higher than August’s reading of 43.6, and it now appears this weak August figure was largely due to planned shutdowns and vacations, and less because of weakening market demand.

The production subindex of 52.0 indicates that work levels increased, as they have for most of the year. With new orders lower and production levels up, we should expect a decline in backlogs. And that is what happened, as the backlogs subindex eased back to 40.0. The employment component was exactly 50.0, which means that moldmakers’ payrolls were steady.

The prices received in the moldmaking sector were modestly lower in September, with a subindex of 48.8. The upward momentum in materials prices accelerated a bit, coming in at 61.8. Supplier delivery times resumed their recent trend of gradual expansion, posting a 53.6 in September. The pace of decline in offshore orders was little changed, with the exports subindex coming in at 45.3.

The MoldMaking Business Index is based on a monthly survey of subscribers to MoldMaking Technology magazine. Using the data from this survey, Gardner Research calculates a diffusion index based on 50.0. A value of more than 50.0 for the index indicates that business activity expanded when compared with the previous month, and a value of less than 50.0 means that business levels declined.

Read Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More