The Impact of Direct Modeling in Mold Manufacturing

Direct modeling, a new form of solid modeling, is changing the way many manufacturers think about plastic part design and tooling.

Unlike traditional feature-based modeling, which relies on a sequence of operations to construct designs, direct modeling works on what has previously been called dumb geometry, using feature recognition and other technology to allow direct manipulation of previously frozen solids. Direct modelers offer a simpler modeling paradigm that can allow fast creation and editing, removing a lot of overhead from the CAD, lowering ownership costs and helping manufacturers spend more time focusing on customer value and cutting parts and less time driving CAD.

There are four areas where direct modeling impacts plastics manufacturers: model repair, part design, mold simulation and mold design. In each case, the basic advantages are the same: you don’t have to worry about where a part came from or how it is going to be used to make edits. You can simply take what you have and edit it however you want without fear of rebuild errors, external dependencies, and other hazards of traditional, feature-based CAD.

One problem commonly encountered is dirty customer geometry. CAD parts can often open with flaws such as split surfaces and tolerance issues that can frustrate mold designers and even crash milling machines. Direct modelers rely on clean underlying geometry, so they are very good at detecting and repairing geometric and topological flaws.

When designing plastic parts, many designers miss potential hazards. When manufacturers receive these parts, it can be difficult to communicate necessary changes back to the customer or to make appropriate edits. Direct modeling offers two ways of improving this communication and move forward with the design: (1) direct modelers can edit wall thickness, draft angles and round radii; and, (2) direct modelers can fill in sharp areas, remove sliver surfaces and merge surfaces to create ideal models. To communicate differences, track changes capabilities can show customers what needs to be changed, and the resulting geometry is as precise as other CAD geometry when it’s time to make molds.

If you perform mold flow simulation, direct modeling can typically be used to quickly de-feature complex parts, extract midsurfaces, and tweak geometry to optimize the mold volume. With direct modeling, it’s easy to play what if and converge on the ideal designs that minimize waste.

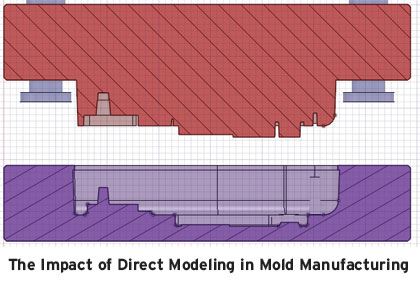

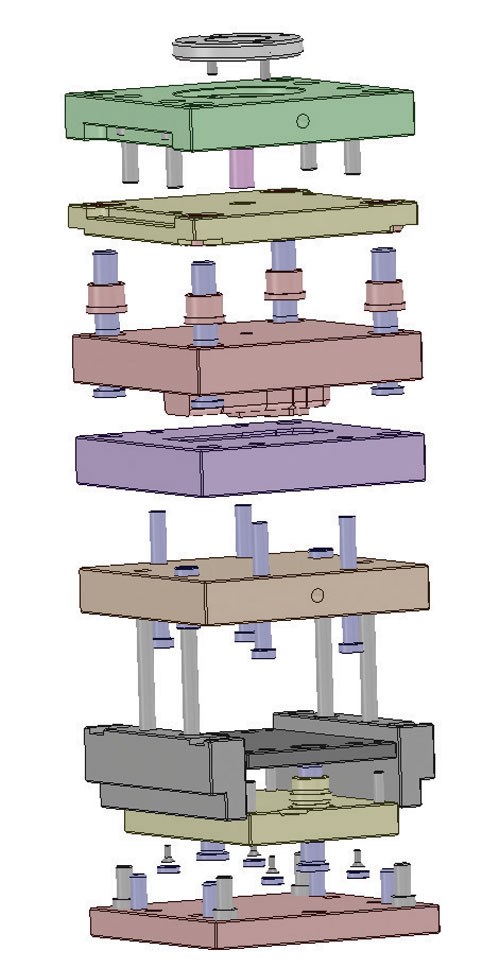

Finally, we all know that molds can be incredibly complex, required hundreds of features in traditional CAD systems. Direct modelers don’t have that problem, and help plastics engineers take a more holistic view of the model. It’s easy to extract cores and cavities and apply them to existing mold base designs. Sprues, gates and runners can easily be created and repositioned. Not only do direct modelers make this easy in 3-D, but they also can help visualize cross sections, where new geometry can be quickly constructed and manipulated.

Direct modeling is a new approach to working with solid geometry, and is now able to handle increasingly sophisticated geometry conditions. It’s practical, no-nonsense approach to getting the job done is starting to change the way the plastics and mold design industry thinks about CAD.

Related Content

-

How to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

-

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

-

Tolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

.jpg;maxWidth=300;quality=90)