The Designer's Edge: More on Part Sticking

Randy reviews how surface finish can impact part sticking with certain materials and offers some mechanical solutions to assist with part removal.

Today I will review how surface finish can impact part sticking with certain materials and I'll offer some mechanical solutions to assist with part removal.

Experience has taught me that the surface finish of cavity steel can impact part sticking, and the most common response is to polish the surface, which makes it shiner. Keep in mind that with some materials, this can create a suction effect.

I recall one incident for which I was brought in to help with a sticking issue. I started by asking what had already been done, which included sending the tool out a few times for polishing. It came back with a shinier finish each time, but this had no effect on sticking. So, I decided to try a different approach; one that would provide a robust solution versus a band-aid. I put a 320 draw polish on the cavity, which eliminated the shiny surface finish. To my surprise the tool ran perfectly with absolutely no sticking issues.

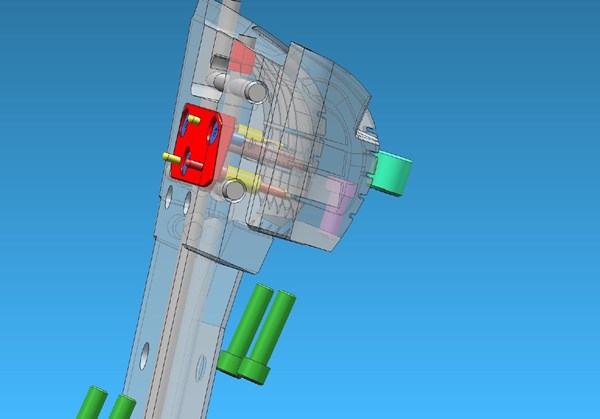

Another sticking issue involves flexible materials with sticking occuring with details on the slides and lifters. For this situation, I do not recommend a mold release. Instead use physical means to remove the part, if polishing and draft do not help. For example, place ejector pins or lifters into the opposing walls to hold the part in place while the lifter or slide pull away. Adding spring-loaded push pins in slides to push the part out while the slide pulls back is an altermative solution. I would typically use the shut-off to push the pin back into position when the slide moves forward.

In some cases, I have used spring-loaded pins in lifters that are activated when the lifter moves forward pushing the part detail out of the lifter. These are mechanically activated with a bump in the lifter pocket that pushes the pin forward and a spring in the lifter that returns it back into position.

For more on this and other Designer's Edge topic, catch up with Randy the Amerimold Expo on June 17 for his talk on "Overcoming Repair and Part Quality Challenges with Design." Click here to register to attend.

.jpg;maxWidth=300;quality=90)