With so much going on in the moldmaking industry, it can be easy to miss the comprehensive list of products and services MoldMaking Technology showcases, both online and in its monthly magazine issues. This week, we look at cutting tool solutions, provided to us by our supplier companies. Ranging from a comprehensive catalog, to high-penetration drill systems and micro end mills, this list gives you a variety of new or proven solutions for your cutting tool needs.

Interested in more cutting tool solutions? Be sure to check out the Cutting Tools Zone for the latest products and services MMT’s comprehensive list of suppliers offer, or view our supplier database.

Walter unveils its high-speed, high-feed MC025 Advance and MD025 Supreme solid carbide milling cutters, which offer near net roughing and tackles pocket, groove and freeform surfaces. A single grade of the MC025 Advance is offered for universal applications for steel, stainless steel, cast iron and materials with difficult cutting properties. The Walter MD025 is offered in two separate grades for application customization.

Taiyo Koki, a DMG Mori company, introduces the Taiyo Koki CVG-6T grinding machine, which enables more precise tolerances and increased productivity. It retains a grinding range of 50 mm-600 mm (ID grinding range) and a maximum 600 mm (OD grinding range).

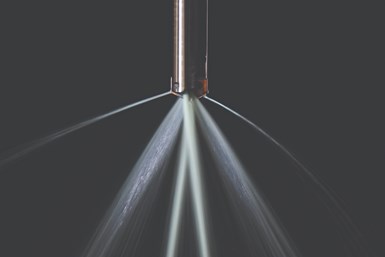

Allied Machine and Engineering highlights its high-penetration drilling system, the T-A Pro, which combines material-specific insert geometries, a redesigned drill body and a proprietary coolant-through system to allow penetration rates which the company says run at speeds nearly 30% faster than other high performance drills on the market. The drilling system will be available in October 2020.

Precision Twist Drill (PTD), Union Butterfield and Dormer are just a few brands representing cutting tools and accessories that Dormer Pramet has created for MRO professionals. Easy to select and comprehensive for MRO needs, Dormer Pramet has identified drills, taps, dies, reamers, end mills and rotary burrs that will deliver reliable and cost-effective results in portable and machine applications and in a wide range of operating conditions for various materials.

Thinbit, manufactured by Kaiser Tool Company Inc., introduces a toolholder option that takes advantage of the full line of inserts for grooving, threading, face grooving and custom applications. Compatible with CNC, Swiss and conventional machines, its design improves rigidity and increases cutting performance.

Tungaloy’s DeepTri-Drill line of indexable insert gun drills for drilling deep holes, now feature FH3135 grade guide pads. They retain high thermal crack resistance when used with water soluble oils, offering an eco-friendly alternative to machining, and offer a smooth entry into the guide bushing or pilot hole.

Oelheld adds SintoGrind TC-X 630 as an entry level product to its flagship and perennial best-selling SintoGrind series. The SintoGrind TC-X 630 is designed for flute grinding, profile grinding, and outside and inside diameter grinding for a variety of materials.

Sunnen Products Company offers a series of drill heads, inserts and pads that are directly interchangeable with Sandvik deep-hole drilling tools. The new line, Sunnen DirectDex, features BTA/STS (single tube system) and DTS/Ejector (double tube system) style deep-hole drilling tools.

Big Kaiser expands its jet-through hydraulic chuck line to include the BCV interface and additional inch sizes. The HDC jet-through type holders are ideal for high-precision five-axis machining and fit nearly any application in the automotive, aerospace, medical, and die and mold industries.

Available in solid carbide and CBN designs, Emuge Corp. offers its new micro end mills product, designed for high precision and difficult materials. More specifically, the solid carbide micro end mills are designed for high precision machining applications up to 55 HRC and the CBN micro end mills for applications up to 66 HRC.

RegoFix introduces the powRgrip toolholding collet system, which generates extremely high clamping forces equal to and, in most instances, higher than shrink-fit holders. The system uses the mechanical properties of the holder material to generate tremendous gripping force with tool run-out below 0.0001".

Seco Tools has expanded its line of square shoulder milling cutters with the Double Turbo, and its ZOMX16 inserts. The cutters improve roug-hing operations and reduce power consumption in steel, stainless steels, cast iron and high-temperature alloys; the inserts incorporate a double-sided design for cost-per-edge savings and smooth surface finishes.

The Hoffmann Group has launched its 2020/2021 catalog, an updated and expanded version of the comprehensive book for quality German cutting tools, hand tools, workstations and storage options. The catalog offers more than 90,000 items.

The YG-1 ENMX high-feed mill 4 is a new high-feed milling series developed to meet the most stringent demands of versatility, productivity and process stability for today’s applications. The inserts are made 20-25% thicker for normal flank wear without encroaching on the secondary edge.

.png;maxWidth=300;quality=90)