Striking Gold with New Cutting Tools

Here are a few examples of overall design trends spotted at a recent unveiling of new Ingersoll cutters, as well as brief descriptions of products designed specifically for mold manufacturing applications.

Calling Ingersoll Cutting Tool Company’s recent “Gold Rush” seminar well-attended would be an understatement. From my lofty perch in the balcony of the Cleveland Public Auditorium, a rough count of rows of chairs revealed at least 700 attendees at last Tuesday’s event, although I wouldn’t be surprised if the formal count was more than that.

What had all these folks come to see? An overview of the company’s latest offerings, courtesy of Jacob Harpaz, president of the IMC Group, Ingersoll’s parent company and the world’s No. 2 cutting tool manufacturer. Broken only by coffee breaks, lunch, and the occasional video or performance by classical musicians and dancers, Harpaz offered a series of presentations that lasted all day, with seemingly no break in enthusiasm, either.

Harpaz certainly had plenty to be excited about. More slides than not had the word “new” splashed across them in bright red lettering to denote a fresh insert or cutter design, or at least an evolution from a previous offering. There’s no substitute for being there, and there simply isn’t space to cover it all here, but I did notice some trends from offering to offering. These include:

*Proprietary surface treatment. In keeping with the title of the event, all cutters on display feature the company’s custom Gold Rush post-coating treatment. By shaving microns off the top layer of the insert surface, this treatment removes microscopic thermal cracks and other imperfections created as natural byproducts of the coating process. This is said to reduce stress, improve tool life and ensure smoother chip flow. (Speaking of coatings, the company and broader industry have shifted to using more PVD than CVD coatings, a topic we covered after a different Ingersoll event last year.)

*Secure insert clamping. Harpaz repeated some variation of the phrase “you can’t rely on the head of the screw” over and over again throughout the day as he cycled through the company’s varied offering of new products. As the weakest point in the entire tool assembly, the screw securing the insert to the cutter body is subject to break due to machining forces. One common strategy Ingersoll employs to prevent this is designing pocket shapes that form a dovetail interface between the insert and tool body. Another is the use of large, angled mounting screws.

*Coolant holes. Many products featured channels through the cutter body to direct coolant to the cutting edge. This ensures proper lubrication and chip evacuation while protecting against high temperatures.

*True 90-degree shoulders. Various offerings, such as the HiPos Trio and DiPos Hexa, feature true 90-degree angles between insert and work, thereby minimizing setups and easing machining of straight-walled channels and pockets.

*Positive geometry. Judging from the offering on display, high-feed cutting strategies that depend on positive cutter geometry remain the method of choice for removing lots of material in a hurry.

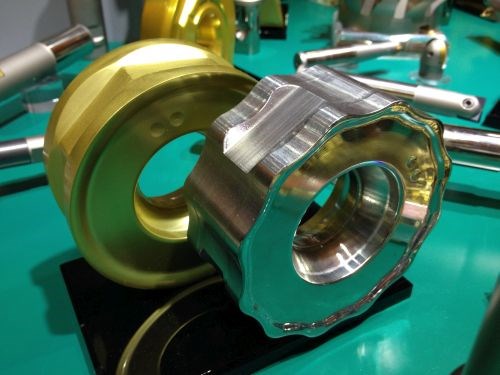

Between presentations, attendees had the opportunity to get a first-hand look at various Ingersoll cutters at various displays set up in the lobby of the Cleveland Public Auditorium.

Although not entirely universal, these trends were in evidence throughout the line, and cutters designed specifically for mold manufacturers were no exception. Here are a few that caught my eye:

*FormMasterR. This line employs two varieties of button inserts: straight and serrated. The latter is said to reduce vibration in long overhangs by breaking machined material into shorter chips. Both types can be mounted in the same tool body. Learn more.

Large models of the FormMasterR's round and serrated inserts. Although cutting edges on both inserts are continuous and fluid, the middle portion is divided into sections to ensure proper fit within the pocket.

*Pro Trio. Featuring double-sided inserts with two cutting edges each and three effective flutes for better performance, this tool is said to be ideal for free cutting at high feed rates. Learn more.

*Finish Ball+. Designed for finishing and semi-finishing applications, this indexable ball mill features coolant channels in the insert itself, which seats in the pocket in such a way that clamping mistakes are virtually impossible. The line is also available with square-cornered inserts, mountable in the standard shank and a special version, for machining corner radii. Learn more.

Cutting tools aren't the only products available from Ingersoll. The company also showcased these Typhoon high-speed jet spindles, which, in contrast to pneumatic and electrical designs, are driven entirely by coolant flow. Learn more.

Read Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)