Pumping Up Molding Plans

Over at Pyramid Plastics, the custom injection molding business of Industrial Molds Group, plans call for purchasing 10 new Toshiba injection molding machines at the rate of one machine per quarter over the next two years.

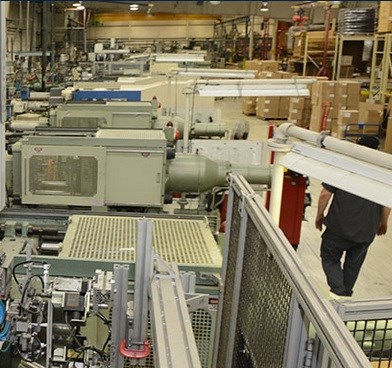

Over at Pyramid Plastics, the custom injection molding business of Industrial Molds Group, plans call for purchasing 10 new Toshiba injection molding machines at the rate of one machine per quarter over the next two years, and they have already added two new presses, a 55-ton and a 90-ton Toshiba press.

According to Tim Peterson, Vice President of Industrial Molds Group, Pyramid Plastics currently has 42 presses including some large-tonnage machines. The new presses will replace some of the older equipment. They don't anticipate growing the number of presses, “just the technical capabilities” the new equipment has to offer to enable Pyramid Plastics to better serve its customers.

“We’ll most likely reduce the number of presses at Pyramid and focus more on improving productivity, and technical precision processing capabilities with an emphasis on medical molding with presses under 500 tons,” he says. “We’re anticipating adding at least one two-shot injection molding machine as well.”

The facility upgrade also calls for the addition of a clean room or “white” room to enable Pyramid’s plans to focus on medical components. Those plans have not been finalized as yet.

As a part of Pyramid Plastics’ strategic planning, the company will be focusing more sharply on customers who fit the company’s business model and goals for growth.

Pyramid Plastics works closely with Industrial Molds to provide its customers with mold design and engineering services, including mold building. Pyramid also offers mold tryouts and qualification, and process validation services for Industrial Molds, and a variety of secondary operations.

You can visit Industrial Molds and Pyramid Plastics at NPE at Booth #S-22144.

.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)