Experience, Knowledge Base, and Creativity Give Tri-Par An Edge in Molds for High-Flow Material Parts

Expertise in building molds for parts made from highly-engineered materials and automation for molding gives Tri-Par Die and Mold Corp. key mechanisms for growth.

Using innovation and experience, Tri-Par Die and Mold provides precision, tight-tolerance molds and offers complete, turnkey production cells. Watch this video to get a closer look.

Where does Tri-Par excel regarding its mold engineering and building expertise?

David Plocinski, General Manager: We build many molds for parts made with highly-engineered materials like high-temp LCP (liquid crystal polymer) materials, glass-filled nylons, and high-melt-flow resins. We run a lot of glass-filled materials in our molding department, so we continually work to ensure that the molds can withstand resins that contain up to 43 percent glass in them because these materials are extremely abrasive and can cause extensive mold wear if not built and maintained properly.

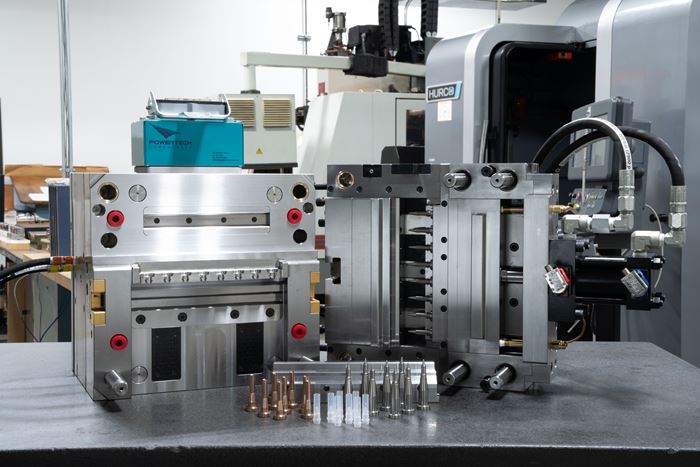

We build most of our new molds for the microbiology research industry. It's not medical; it's more for nonmedical applications. An example would be small vials and caps for DNA testing. The challenge with these types of molds is that the parts can have extremely thin walls, as thin as 0.007 inch to 0.008 inch wall thickness, molded using high-flow materials (usually propylene—clarified, nucleated, anti-stat, higher end types of propylene). These types of propylene flow very easily and can flash very easily, so our tolerances on the molds must be extremely tight and for good reason. If you were doing DNA testing, for example, rubber gloves are required to avoid contaminating the samples. But if the vial has flash or hard gates on it, and the gloves get cut on them, you risk contamination and any number of other issues. So, gating is critical, and we’ve used straight hot-runner systems, valve-gate systems, even three-plate molds to work around and resolve the various challenges our customers’ part designs present to us. We have become very well versed in engineering these molds; our team puts its vast knowledge of plastic materials, production injection molding, heat profiles, and more into every project to produce a mold that provides great value to the customer. High productivity molds with minimal down time.

We also get creative with our venting and getting the air out to prevent knit lines or holes in the bottoms of the vial wells. For example, we recently built a mold for a small vial. During sampling, we saw that it was trapping air right at the end of the vial well and material was not filling properly. Based on our team’s experience with similar issues, we put a vent pin inside of the core pin. The vent pin was only about 0.060 inch in diameter; we wired a hole so that the vent pin could be installed and allow the trapped air to vent out. Then we designed it so that it was a moving vent, which made it self-cleaning and it will not clog up. It seems like such a simple solution, but it solved a crucial problem for our customer.

How are you able to leverage your moldmaking team’s knowledge and expertise across Tri-Par’s operations?

Plocinski: The mold makers in our tool room are not just mold builders. Yes, they build molds, and they can repair molds. But they are also machinists and know quite a lot about hydraulics and pneumatics because of the nature of our industry. We also have experience with unscrewing molds and have worked with servo systems, and so we can leverage all that knowledge into designing and building automation for the molding side of the business. These systems are very simple yet highly productive automation solutions.

I like the K.I.S.S. method, keep it simple. We've been able to build some great pieces of automation for extremely low cost that have provided us extraordinary returns on investment. Previously, in some instances, we would have a machine operator sitting at a molding press 100 percent of the time performing a post molded secondary operation while the mold was running. Now, using simple automation, they interact with the molding cell 5 percent to 10 percent of the time, swapping out empty boxes for boxes filled with parts. They weigh count each box, put it on a skid and move on to tend to other machines. Our molding group and tooling group worked together and came up with a design that ultimately improves our bottom line. Even though it's the customer’s mold and part, I will invest in automation or mold enhancements if it makes sense. It’s beneficial for our customers and Tri-Par.

I believe the way we leverage our experience, knowledge base, and continuous improvement strategies into mold building and production injection molding provides great value to our customers. This has been especially effective since moving three years ago into a new, larger, 60,000-square-foot facility, which allowed us to consolidate our tooling and molding operations under one roof. This allows our mold makers to interact with the molding department and see first-hand how well our molds are performing in production. This firsthand learning is priceless in terms of applying lessons learned to future mold builds. We have 24 molding machines ranging from 50 tons all the way up to 720 tons, running three shifts 24 hours a day, six days a week. We have full tool-room capabilities, including high-speed CNCs, sinker EDMs, grinders, and other equipment.

What does the future look like for Tri-Par? What growth strategies are in place?

Plocinski: We have grown, and we believe that growth will continue. We’re bringing in more customers from different industries, and we have upgraded equipment, including purchasing a new Charmilles sinker EDM and new Hurco high-speed machining centers. We’re looking to expand by leveraging our knowledge and expertise into different industries and markets including building molds for more complex threaded parts and getting back into molds for automotive lighting.

One exciting project that we did recently is a full, turnkey cell for a customer whereby the customer drop-shipped the molding machine to us and had us build the mold for that machine. When the mold was completed, we installed the molding machine, set up the mold and debugged the entire cell in our facility. Then the customer came in; we qualified the mold and molding cell. Once approved, the entire cell including the molding machine and mold were shipped to California for installation and production. It isn’t the first time we have done this. The same customer drop-shipped a two-shot molding machine to us and had us build three two-shot molds. This cell included the two-shot molding machine with servo rotary platens. Again, we debugged and qualified all three two shot molds and molding cell, then shipped the machine, auxiliary equipment and all three molds to the customer’s plant. With a larger facility, we can provide more and larger turnkey solutions.

.jpg;maxWidth=600)

.jpg;maxWidth=300;quality=90)