Leveraging Limited Resources

This moldmaker credits cross-training, unattended machining and a knack for problem-solving for its ability to survive and thrive through tough times.

In some ways, MoldMaking Technology’s 1998 profile of B A Die Mold reads as if it were written yesterday. Among the chief challenges facing the Chicago-area mold manufacturer, company founder Alan Petrucci cited a shortage of skilled workers and low-cost, overseas competition, topics that remain very much in vogue. Then, as now, the shop’s success depended on its willingness to adapt to new realities, its drive to keep up with technology, and its flair for creative problem-solving.

Yet beyond these broad strokes, B A Die Mold is a very different company than it was 15 years ago. Petrucci remains quite active in the business, but his daughter, Francine, has taken the reins as president. The facilities are larger and more modern, and the equipment is more sophisticated. The staff is leaner, the skill sets of individual employees are broader, and more work than ever before runs lights-out. Finally, B A Die Mold has parlayed a core competency into a new product line that serves as a direct source of revenue.

Peak to Valley

After Petrucci founded B A Die Mold in 1968, the company outgrew three different facilities before settling into a 10,000-square-foot plant in Lisle, Ill., in 1975. By the time MMT profiled the shop in 1998, it had built a solid reputation as a supplier of plastic injection molds, particularly complicated multi-action tooling and molds for threaded parts. B A Die Mold was doing well by any measure, Francine Petrucci recalls—well enough, in fact, to begin planning yet another expansion.

Fed up with low ceilings, insufficient power and other problems with its aging plant, the business moved into its current 16,000-square-foot facility in Aurora, Ill., in 2000. By that point, however, the shop was down to a fraction of its former staffing levels. A significant cause of this decline was a major exodus of mold machining work to low-cost overseas suppliers, a development that seemed to happen overnight, she says.

More With Less

Work once viewed as an art form had become commoditized, and attempting to compete on price alone would be futile for a shop committed to quality and reliability. So B A Die Mold began to shift its customer base from various custom molders to larger OEMs that appreciated what the shop had to offer. Having shed their own tooling and engineering departments in many cases, these companies needed not just a supplier, but a problem-solving partner. Although these customers hailed from different industries, the work itself didn’t change much, Petrucci says. The company could continue to thrive on quality and precision. However, it would also have to meet tighter delivery schedules and provide additional services like prototyping, all with a significantly leaner staff.

The shop’s success in this endeavor is evidenced by the fact that sales are higher than at any point during the ‘90s, yet costs are lower. In part, that’s because each member of its leaner staff “wears many hats,” says General Manager Michael Duquette, who instituted a formal cross-training program about six years ago to empower shopfloor operators. Enabling, say, quality-control personnel to also operate EDM machines not only keeps work flowing when team members are on vacation or otherwise unavailable, but also helps alleviate bottlenecks when certain areas become busier than others. Employees also have more to offer when it comes to solving problems. “Anyone might have valuable input on the big picture of how a job might flow through the shop,” Petrucci explains. “There’s more of an ‘I can do that’ mindset, as opposed to a ‘They can do that’ attitude.”

Another important change is that a single operator typically programs and runs multiple machines. Unattended machining during the night shift has also been critical. In fact, Duquette says the share of lights-out work has increased from about 10 percent of total production to about 30 percent within the past 10 years. Again, much of that improvement can be attributed to efforts to empower the people on the shop floor. Moving from offline to conversational programming, for example, has enabled employees to use their own knowledge and experience to schedule and program this work, which typically involves repetitive machining routines, lengthy cycle times, and open geometry that doesn’t require fine, difficult cuts.

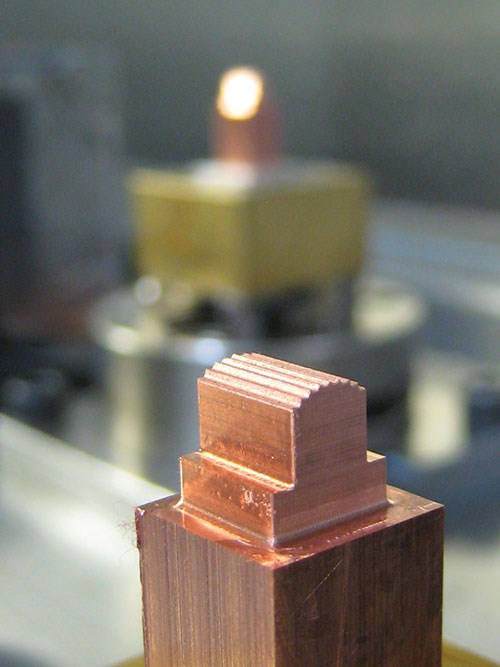

Of course, raw technological improvements can’t be discounted. For example, software that enables extracting EDM electrodes directly from 3D solid models of the corresponding part geometry was critical to getting electrode development out of engineering and onto the shop floor, Duquette says. Likewise, custom fixture plates that accept standardized holders from Erowa ensure location repeatability from workpiece to workpiece and from machine to machine without re-referencing. This system was a major factor in enabling operators to run multiple machines and prepare lights-out work more efficiently. He also credits advancements in machine tools, CNCs and cutting tools for faster, more reliable production.

Idea to Opportunity

In the short term, the shop aims to continue doing more with less by implementing pallet systems, and, eventually, robotics. These sorts of investments will be critical to future competitiveness, but Duquette cautions that the shop can’t rely on technology alone. “It would be great to replace our equipment every year, but the reality of business dictates otherwise.”

For that reason, management agrees that the future success of both B A Die Mold and the U.S. industry as a whole will depend not just on technology, but also on knowledge and ingenuity. In fact, the shop has already capitalized on one particular area of expertise. The PERC (Programmable Electric Rotating Cores) system was originally developed for in-house use, but it now brings in a steady stream of revenue on the open market. Molds for threaded components require rotating cores to unscrew and eject parts without damaging the threads. Rather than hydraulic racks that can become long and unwieldy for parts with many threads, the PERC system employs programmable servomotors to ease setup and enable the use of smaller presses, among other advantages. “We realized that we’d come up with a great idea, and we decided to patent it,” Ms. Petrucci says. “But we’re constantly solving problems creatively, and that really goes for all moldmakers—it’s just what we do.”

Related Content

Dynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

Read MoreTackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreMold Maintenance Continues to Matter: Enhanced Training Program in a New Facility

I attended a MoldTrax mold maintenance workshop in 2019 and shared my experiences, and despite changes in ownership, the workshop's remarkable value endures, as discussed in a recent Q&A with the current leadership.

Read MoreMMT Chats: Westfall Technik Talks Runnerless Micro Molds and More

Westfall Technik sits down with MMT Editorial Director Christina Fuges to discuss their new micro hot runner technology, the closeness of the moldmaking community and the importance of integration. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)